Recently, the Laboratory of Thin Film Optics and National Laboratory on High Power Laser and Physics from the Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences have carried out co-operative research, and have made progress in the research on the picosecond laser mirrors based on HfO2-Al2O3 mixture materials. The corresponding research results were published in Optical Materials Express. Lasers operates in the pulse width of several picosecond (ps) regime is usually used for high energy density related research, such as OMEGA EP, NIF ARC, and SG-II-UP PW. Mirror coatings are key components in picosecond laser systems, and their ability to deliver high-intensity picosecond laser pulses is limited by the laser-induced damage threshold (LIDT). In recent years, optical coating components based on mixture materials have gained wide attention due to their superior performance over pure materials under nanosecond and femtosecond pulsed lasers. Mixture materials are expected to enhance the performance of optical coatings under picosecond pulse laser irradiation.

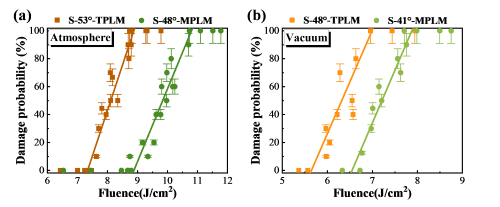

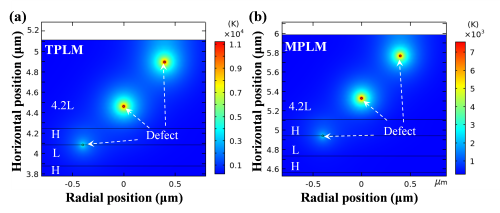

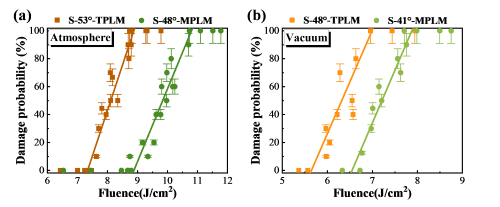

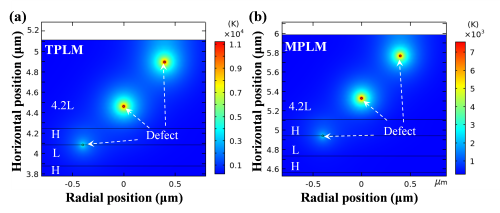

Researchers deposited a mixture-based picosecond laser mirror (MPLM) coating using HfO2-Al2O3 mixture material and pure SiO2 material as high/low refractive index materials through electron beam evaporation. For comparison, a traditional picosecond laser mirror (TPLM) was prepared by alternating deposition of pure HfO2 and SiO2 materials. The optical properties, microstructural, and mechanical properties of MPLM and TPLM were studied, as well as the LIDT (laser pulse width: 8 ps, laser wavelength: 1053 nm) and damage morphology in atmosphere and vacuum environments were investigated. The results indicate that MPLM exhibits higher LIDT in both atmosphere and vacuum environments. The typical damage morphologies indicate that the laser induced damage of the two coatings were closely related to the electric field distribution, film defects, and film stress. The finite element simulation results indicate that the higher LIDT of MPLM may be attributed to the mixture material reducing the temperature rise generated by the multi-layer film under laser irradiation.

This work was supported by the National Natural Science Foundation of China, and Youth Innovation Promotion Association of the Chinese Academy of Sciences.

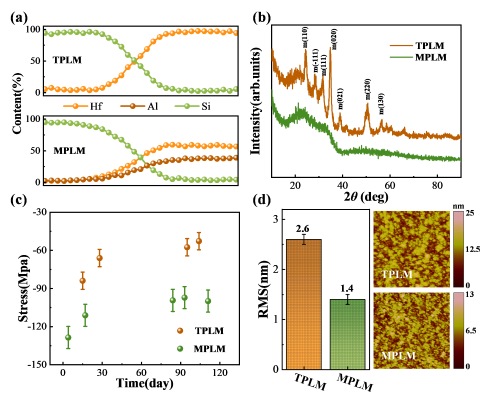

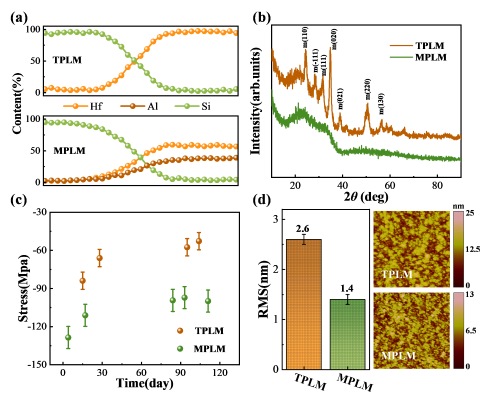

Figure 1. (a) Elemental percentage profiles from the low-n layer to the high-n layer, (b) XRD spectra, (c) stress aging behavior, and (d) surface morphologies of the TPLM and MPLM coatings.(Image by SIOM)

Figure 2. Single-pulse damage probability as a function of the input fluence, measured in (a) atmosphere environment, and (b) vacuum environment, respectively.(Image by SIOM)

Figure 3. Simulated temperature distributions of absorbing defects located at the positions of the first, second and third E-field peaks in the (a) TPLM and (b) MPLM coatings, respectively.(Image by SIOM)

Article website:

https://doi.org/10.1364/OME.483052

Contact:

PENG Zexu

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: pengzexu@siom.ac.cn

Web: http://english.siom.cas.cn/