Recently, the Laboratory of Precision Optics Manufacturing and Testing Center of Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences has made new progress in the research of laser high-precision figuring theory and technology. For the first time, laser beam figuring can achieve the full-spatial-frequency errors convergence of nanometer precision under negative stress. The relevant research results are entitled "Densi-melting effect for ultra-precision laser beam figuring with clustered overlapping technology at full-spatial-frequency " published in Optics Express.

With the development of modern optical technology, fused silica optics are widely used in high-power laser systems, but with the continuous improvement of optics surface quality requirements, the current sub-aperture polishing technology will inevitably introduce impurity pollution, which seriously limits the performance of optics in high-power optical systems. At present, laser processing has the advantages of non-contact, no polishing contamination and flexible processing, which is expected to become a key technology to break through the existing processing bottleneck, but the existing laser ablation and laser polishing technology cannot meet the accuracy requirements of form error and roughness at the same time, which leads a huge challenge to laser ultra-precision machining.

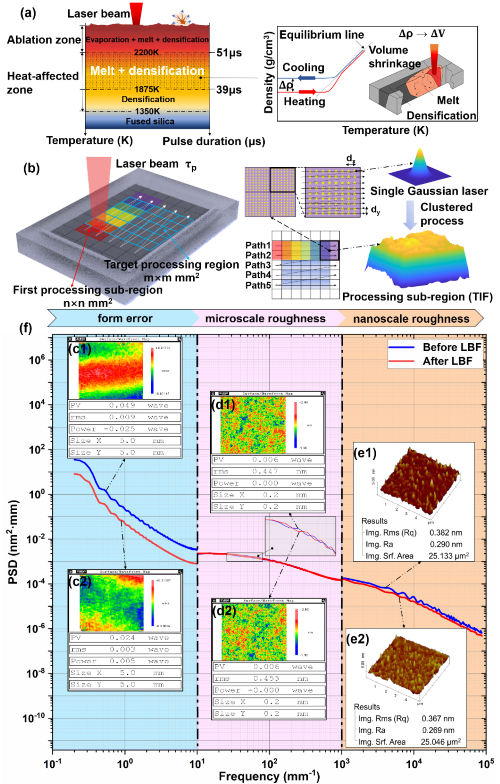

In order to solve the above problems, the "densi- melting" effect was found for the first time in this study, through the volume contraction caused by the densification effect and the surface smoothing caused by the melting effect, the convergence of surface shape and roughness was realized synchronously. This effect breaks the inherent laser ablation "reducing material" figuring process, and successfully reveals the nanoscale "equal material" figuring mechanism. In addition, the study also proposes an overlapping clustered process, which is modified by overlapping scanning of laser processing subregions (removal function), reducing the control data volume by three orders of magnitude and without introducing scanning mid-spatial-frequency ripples. By the combination of theory and technology, comparing the results before and after the laser beam figuring, the form error RMS converges from 0.009λ to 0.003λ (λ=632.8nm), the micron-scale roughness changes from 0.447nm to 0.453nm, and the nano-scale roughness decreases from 0.290nm to 0.269nm. The stress birefringence changes from 2.79nm/cm to 3.94nm/cm (meet the requirements of optical systems <5nm/cm). This is of great significance for the ultra-precision manufacturing of optical components.

The relevant work has been supported by the key research and development Program of the Ministry of Science and Technology, the National Natural Science Foundation, the Shanghai Qimingxing Sailing Program, and the Youth Innovation Promotion Association of the Chinese Academy of Sciences.

Fig. 1. LBF of full-spatial-frequency error convergence. (a1) Form error before LBF; (a2) Form error after LBF; (b1) Microscale roughness before LBF; (b2) Microscale roughness after LBF; (c1) Nanoscale roughness before LBF; (c2) Nanoscale roughness after LBF; (d) PSD curves of the material surface before and after LBF.(Image by SIOM)

Article website:

https://doi.org/10.1364/OE.492499

Contact:

PENG Zexu

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: pengzexu@siom.ac.cn

Web: http://english.siom.cas.cn/