The researchers in the Laboratory of Information Optics and Optoelectronic Technology at the Shanghai Institute of Optics and Fine Mechanics (SIOM) of the Chinese Academy of Sciences (CAS) have recently made new progress in high-accuracy polarization measurement in deep ultraviolet band. Utilizing a Brewster wedge plate as a polarizer, a large beam at 193 nm is effectively polarized with a large separation angle. A pre-polarizing and beam-splitting structure is used to reduce power drift. The measurement accuracy is significantly improved by making full use of all measurement data based on priori physical knowledge. The related results are published online in Optics & Laser Technology under the title of "Performance measurement technique for 193-nm depolarizer" on Dec. 15, 2022.

Polarization control is a key technology for 193-nm immersion lithography. A variety of polarization control elements have been used in immersion lithography systems. An essential element is the depolarizer. However, the existing performance measurement methods for 193-nm depolarizers used in immersion lithography are primarily online detection methods. Offline measurement is challenging because these depolarizers utilize a large beam size and produce a small degree of polarization (DOP).

The main difficulties are as follows: there are few birefringent materials available in this band, which makes it difficult for the polarizer to meet the measurement requirements in terms of separation angle and polarization extinction ratio (PER); the excimer light source used for measurement has obvious intensity fluctuation; the accuracy of the ultraviolet energy meter is far from meeting the measurement requirements.

In view of the above difficulties, the researchers have made breakthroughs one by one, and finally achieved high-accuracy performance measurement of the 193 nm depolarizer.

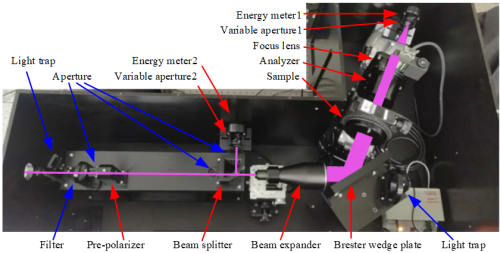

The researchers bypassed the traditional principle of using material birefringence to achieve polarization. Based on Brewster's law, a fused-quartz wedge was used to achieve high PER and large separation angle for a large beam at 193 nm. This scheme does not depend on the transmittance and birefringence of the material, and can achieve a high PER of more than 5000:1 within the incident-angle error range of ±0.5 °. Due to Brewster's law and the wedge angle, only the desired polarized beam is emitted in a considerable angle range.

In addition, the researchers designed a pre-polarizing and beam-splitting structure, which greatly reduces the influence of polarization fluctuation and light intensity fluctuation on the measurement.

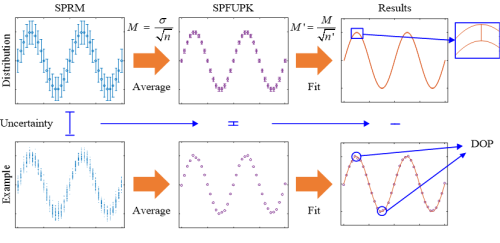

Aiming at the key problem that measurement accuracy is difficult to meet the demand, the researchers have creatively introduced prior knowledge in the measurement, that is, the output light can always be divided into a depolarized or circularly-polarized component and a linearly-polarized component according to the polarization decomposition; light intensity of the former is constant at each analyzer angle, whereas that of the latter follows Malus' law.

Based on this prior knowledge, the measured data can be fitted using a sine curve with a given period to obtain the intensity curve that approximates the true value. The absolute error and uncertainty of DOP measurement were highly consistent with the theoretical predictions and were all less than 0.1 %. After the single-point repeated measurement and overall fitting, the measurement uncertainty was significantly reduced. In the experiment, the optimal measurement uncertainty is obtained as low as 0.058 % (the theoretical prediction value is 0.053 %), while the uncertainty of the used energy meter is as high as 8 %.

This technique can be used for offline measurement of performance of the depolarizer used in 193-nm immersion lithography. It can serve as a comprehensive reference for related work on high-accuracy polarization measurement at ultra-short wavelengths.

Fig. 1. Experimental setup. (Image by SIOM)

Fig. 2. Schematic showing reduction of measurement uncertainty. (Image by SIOM)

Article Website:

https://doi.org/10.1016/j.optlastec.2022.109028

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/