The Research Center for Laser Intelligent Manufacturing of Shanghai Institute of Optics and Fine Mechanics (SIOM), Chinese Academy of Sciences (CAS) has carried out experimental research on resistance-laser spot welding technology for aluminum/steel dissimilar metals and achieved a significant improvement in the mechanical properties of aluminum/steel welding joints. The related research results were published in Materials & Design under the title of "Hybrid resistance-laser spot welding of aluminum to steel dissimilar materials: Microstructure and mechanical properties" on August 3, 2022.

In response to the poor performance of aluminum/steel dissimilar metal welds, in this research, the researchers used a resistance-laser spot welding technique to weld the combination. First, the spot welds are made by resistance spot welding connection technology, which is the mainstream in automobile manufacturing, and then circular welds are made around the spot welds by laser flight welding technology.

Researchers found significant improvements in the mechanical properties of aluminum/steel joints were achieved by changing the joint structure and controlling the thickness of brittle intermetallic compounds. In the research, the research team found that resistance spot weld had a considerable tensile-shear load but poor ductility and energy absorption due to the presence of a weak bonding area around the periphery of the joint, which facilitated the crack initiation and rapid propagation. The following laser spot welding process was conducted in the weak bonding area of the resistance spot welding joint, which inhibited rapid propagation of the cracks along the faying interface avoiding the interface fracture.

Aluminum/steel dissimilar metal welding technology has broad application prospects in the context of automotive light-weighting. However, due to the huge difference in thermophysical properties between aluminum/steel, a large amount of brittle intermetallic compounds and cracks are formed in the weld after welding, resulting in the aluminum/steel joints cannot meet the body application requirements.

So far, in order to overcome these challenges, many published works mainly focus on the optimization of welding parameters and tailoring of alloying elements in welds, aiming at reducing the formation of brittle intermetallic compounds in the weld and improving the mechanical properties of the joint. However, high-quality aluminum/steel joints that can meet a wide range of applications have not yet been obtained.

Therefore, this work provides a new technical solution for aluminum/steel dissimilar metal welding.

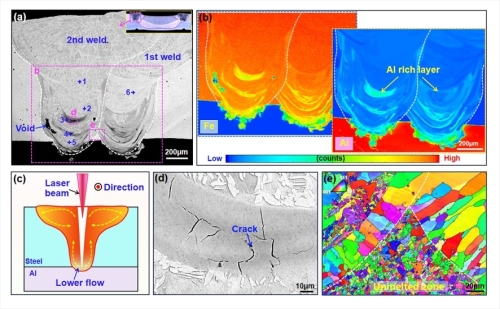

Fig.1 Microstructure and element distribution of laser welds. (Image by SIOM)

Fig. 2 Microstructure and element line distribution of aluminum/steel interface. (Image by SIOM)

Article website:

https://doi.org/10.1016/j.matdes.2022.111022

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/