Recently, researchers from Laboratory of Thin Film Optics, Shanghai Institute of Optics and Fine Mechanics (SIOM), Chinese Academy of Sciences (CAS), has systematically studied the damage mechanism of low-density defects affecting large-aperture pulse compression gratings (PCGs) application. The relevant results have been published in Optical Materials Express on Feb. 1, 2022.

PCG is the core optical element of the high-energy petawatt laser system, and its damage is the key factor restricting the output capability of the picosecond high-energy petawatt laser system. Considering the fabrication characteristics of large-aperture PCGs, as well as the working conditions of PCGs, test methods with a small number of samplings employed in previous studies were hardly identify the damag e precursors comprehensively.

Researchers performed the improved laser damage test method with a relatively large sampling area to analyze the grating fabrication process. Through statistical analysis of the damage characteristics of thousands of samplings per fluency, the critical low-density defects damage problems in the PCGs application were accurately described.

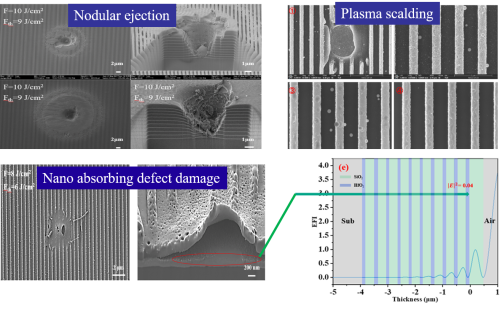

It is found that the LIDTs of multilayer dielectric films decreased by approximately 30% after being fabricated into the PCGs. Damage of the PCGs induced by a nanosecond laser mainly behaves as nodular defect ejection, nano-absorption center damage, and plasma scalding area accompanied by defect damage. The nodular seeds are mostly located on the substrate surface. The nano absorption center is located at the first SiO2/HfO2 interface below the grating structure, and the plasma scalding only involves the top of the grating pillar. Besides, damage morphology dependent on the peak value of the electric field intensity was found.

This study elucidates the fundamental mechanisms inducing the nanosecond laser damage of PCGs and provides the direction for the fabrication optimization of the PCGs.

Figure 1. Comprehensive identification and characterization of PCG damage properties near the threshold. (Image by SIOM)

Article website:

https://doi.org/10.1364/OME.449428

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/