Recently, researchers from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, have proposed a new Mechanism laser damage model for dual-ion sputtered coatings under fundamental frequency laser irradiation, which can match well the different damage morphology characteristics at high and low energies of sputtered dense coatings. The results have been published in the journal Scientific Reports on Feb. 12, 2021.

Dual ion beam sputtered coatings have excellent mechanical properties and environmental stability, making them suitable for use in space laser systems. Laser damage to coatings is a bottleneck in laser systems, and laser damage to sputtered coatings in space is relevant to the stability of the launch and operation of the entire spacecraft mission. The study of the physical mechanisms of laser damage in sputtered coatings is crucial to finding ways to improve the performance of coatings, and current laser damage models cannot provide a good explanation for the phenomenon of large-size peeling from sputtered coatings.

In this research, a new model for laser damage of dual-ion sputtered coatings under fundamental frequency laser irradiation has been proposed and matched to experimental results.

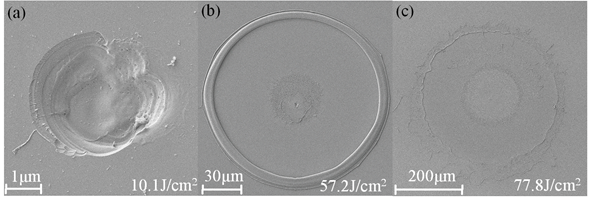

Researchers found that the dual ion beam sputtered multilayer coatings exhibit two typical damage patterns under fundamental frequency laser, one is thermally coupled damage without layer peeling, and the other is a large area layer peeling damage pattern. The large layer peel effect is distinctly different from the honeycomb shape of the e-beam evaporated coatings and the ring ablation shape of fused silica.

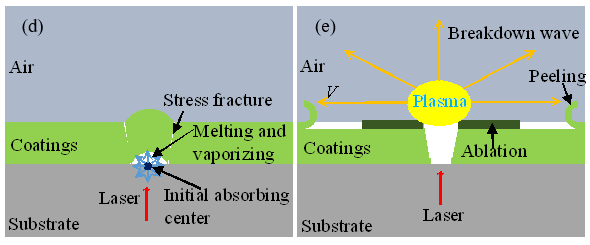

Therefore, researchers proposed a laser damage model based on the correlation between laser energy and air dissociation to explain the phenomenon by calculating the action process of air ionization waves, including the damage process caused by defects and the damage process of shock waves formed by ionized air.

The physical model is validated against commonly used combinations of Al2O3/SiO2, Ta2O5/SiO2, and Nb2O5/SiO2 coatings and is found to be a good match, while the peeling effect is also found to be related to the thermal parameters of the different layers. The analysis of the film damage process can help to improve the resistance to laser damage from the process and design perspectives, while the modified model can be extended to damage mechanisms of other laser materials.

The related work was supported by the Key Project of International Science and Technology Innovation Cooperation between China and Italy, the National Natural Science Foundation of China, the Youth Innovation Promotion Council of the Chinese Academy of Sciences, and the Strategic Pioneer Science and Technology Special Project of the Chinese Academy of Sciences.

SEM morphologies of Al2O3/SiO2 coatings after laser irradiation: (a) close to laser damage threshold; (b) middle laser fluence; (c) high laser fluence. (Image by SIOM)

Schematic diagram of laser damage process: (d) initial defect absorbing laser energy, thermomechanical coupling effect; (e) ionizing air to form plasma, peeling off effects. (Image by SIOM)

Article website:

https://doi.org/10.1038/s41598-020-80304-2

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/