Recently, a research team from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, proposed to use a new design with mixture layers and novel sandwich-like-structure interfaces to meet the challenging requirements of the ideal dichroic laser mirrors. The research article was published on Photonics Research on Jan. 27, 2021, and was highlighted as an Editor's Pick.

Dichroic laser mirrors are usually used as harmonic separators, beam combiners or splitters, and play an important role in many laser applications, including inertial confinement fusion laser, petawatt femtosecond laser, high power fiber lasers, compact Q-switched or mode-locked lasers, and other emerging lasers. The requirements for dichroic laser mirrors continue to increase with the development of laser technology. The ideal dichroic laser mirror for high power lasers requires a significantly different reflection or transmission property and a high laser-induced damage threshold (LIDT) at two different wavelengths of interest simultaneously.

Unfortunately, a traditional dichroic laser mirrors (TDLM) composed of alternating high- and low-refractive-index (n) pure materials often have difficulty in achieving excellent spectral performance and high LIDTs at two wavelengths simultaneously. There is a trade-off between the required optical performance and LIDT.

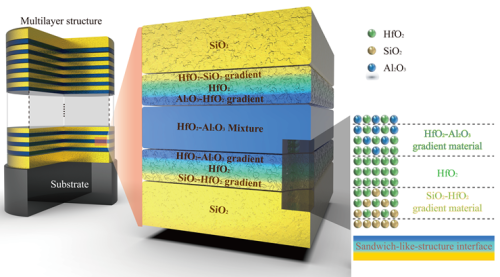

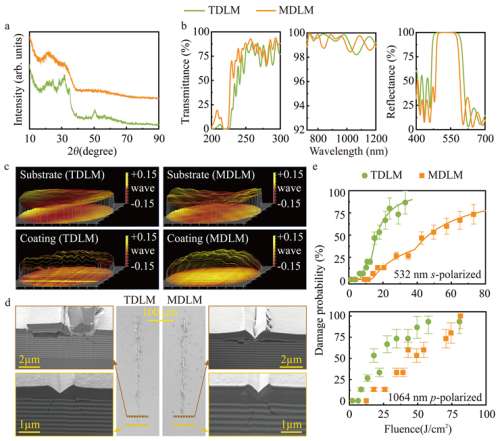

In this work, researchers designed and prepared a mixture-based dichroic laser mirror (MDLM), which uses HfO2-Al2O3 mixture material as a high-n layer with adjustable n and optical bandgap, and pure SiO2 as a low-n material. The interface between the low-n SiO2 layer and the high-n HfO2-Al2O3 mixture layer is a sandwich-like-structure interface (“SiO2-HfO2 gradient material | HfO2 | HfO2-Al2O3 gradient material”), which replace the traditional discrete interface. The MDLM shows excellent spectral performance and improved performance over TDLM with finer mechanical property, lower absorption, and higher LIDT. For both the s-polarized 7.7-ns pulses at a wavelength of 532 nm and the p-polarized 12-ns pulses at a wavelength of 1064 nm, the LIDTs are almost doubled. This MDLM design strategy opens new avenues for improved dichroic mirror coatings and other laser coatings and can benefit many areas of laser technology that rely on high-quality laser coatings.

This work was supported by the National Natural Science Foundation of China; Youth Innovation Promotion Association of the Chinese Academy of Sciences; Strategic Priority Research Program of the Chinese Academy of Sciences.

Fig. 1. Schematic diagram of the proposed MDLM design. (Image by SIOM)

Fig. 2. Microstructure and optical property of the TDLM and MDLM coatings. (Image by SIOM)

Article website:

https://doi.org/10.1364/PRJ.411372

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/