Recently, researchers from the Shanghai Institute of Optics and Fine Mechanics(SIOM) of the Chinese Academy of Sciences (CAS) have proposed a method to refine the feature size of femtosecond laser-induced multiphoton polymerization (MPP) manufacture based on manipulating the content of photo-initiator (PI) in the photoresist. They revealed that small molecules in the photoresist show their diffusion effect during the photo-polymerization process. The relevant study has been published in Optical Materials on Jan. 6, 2021.

Femtosecond laser-induced MPP manufacture is widely used to directly write 3D micro-structures in the fields of Micro-electromechanical Systems (MEMS), micro optics, and biogenetic texture et al. Currently, improvements on the multiphoton absorption cross section of photo-initiator in photoresist and adjusting the focus shape are mostly employed to refine the feature size of the 3D micro-manufacture. By now, the feature size of this 3D micro-manufacture has been achieved 10 nm.

However, through analyzing the photo-physics-chemistry process during MPP, the concentration of PI was considered to be related to the time of duration of the polymerization. Finally, it could decide the feature size of the polymerization structures.

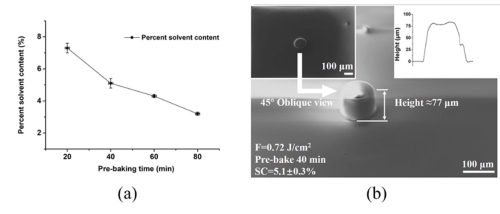

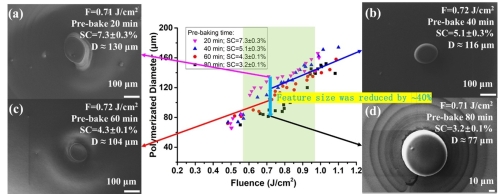

The negative photoresist SU-8, which contains hexafluoroantimonate salt as PI and bisphenol A novolac epoxy as oligomer monomer, was employed for the study. Various pre-baking time was set to investigate the role of PI concentration induced diffusion effect in feature size of the MPP structures. A long focal-length, single pulse femtosecond exposure method was taken to generate oblate MPP structures. Their morphologies were observed precisely. Results show that the feature sizes of MPP structures are reduced by ~40% when the solvent content of SU-8 decreases from ~7% to 4%. The weakened diffusion effect of photo-induced cations due to the less solvent content is contributed to the refining of feature size by restricting the MPP in a much smaller space.

The conclusion shows a new method to achieve finer feature size of MPP manufacture. The diffusion of small molecules, an intrinsic process during MPP, deserves more attention. The study also provides a basis for understanding the employment of photoresists and the development of indigenous photoresist.

The work was support by the National Natural Science Foundation of China and Strategic Priority Research Program of the Chinese Academy of Sciences.

Figure 1. (a) Adding pre-baking time to reduce the solvent content (SC) in SU-8. (b) Morphologies of the oblate MPP dots induced by long focal-length, single pulse exposure. (Image by SIOM)

Figure 2. Statistics of the size of polymerized dots with different SC and exposure fluence. (a), (b), (c), (d) are morphologies of the MPP dots with the SC of 7.3%, 5.1%, 4.3% and 3.2%, respectively. (Image by SIOM)

Article website:

https://doi.org/10.1016/j.optmat.2021.110800

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/