Recently, a research team from the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, improved the laser-damage resistance of 355 nm AR coating by low-temperature PEALD. The work was published in Journal of Alloys and Compounds in April 5, 2021.

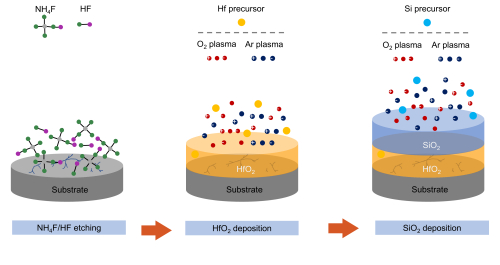

Atomic layer deposition (ALD) shows exceptionally precise thickness controllability, high uniformity, unparalleled conformality, and a relatively high laser-induced damage threshold (LIDT), which is a promising method for preparing thin films for high-power lasers applications. Current attempts to prepare thin films for high power lasers via thermal-ALD focus on using TiO2/Al2O3 or HfO2/Al2O3 layers for near-infrared antireflection (AR) coatings. There are few reports on the preparation of ultraviolet AR coatings by ALD. The studies about electron-beam deposition show that higher LIDT can be obtained using HfO2/SiO2 layers to prepare laser AR films from ultraviolet (UV) to near-infrared. However, high deposition temperature is required for the thermal-ALD grown SiO2 layer, which is not conducive to the LIDT of the HfO2 layer in HfO2/SiO2 coatings. Plasma-enhanced ALD (PEALD) provides similar growth characteristics as ALD and has the advantage of low-temperature growth.

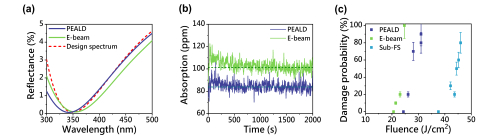

In this work, researchers used low-temperature PEALD to systematically study the laser-related performances of PEALD-grown SiO2 and HfO2 films. It was found that the PEALD-grown SiO2 films showed lower impurity content and absorption and higher UV-laser damage resistance than that of HfO2 films, which makes PEALD-grown SiO2 films suitable for UV laser applications. A double-layer structure of HfO2/SiO2 AR coating for 355 nm laser was designed and fabricated and compared with the AR coating grown by traditional electron beam deposition. The results show that the measured reflectance of the PEALD AR coating at 355 nm is lower than 0.2% and the LIDT (24.4 J/cm2, 7.8 ns) of the PEALD AR coating is higher than that of the electron beam-grown AR coating (20.6 J/cm2, 7.8 ns). This research is expected to provide a new idea for improving the laser damage resistance of UV AR coatings and enrich the deposition technology of UV AR coatings.

This work is supported by the National Natural Science Foundation of China; the Youth Innovation Promotion Association of the Chinese Academy of Sciences; the Shanghai Young Top-notch Talent Program; and the Strategic Priority Research Program of Chinese Academy of Sciences.

Fig. 1. Schematic diagram of the process of low-temperature PEALD AR coating deposition. (Image by SIOM)

Fig. 2. The performance comparison between plasma enhanced atomic layer deposition (PEALD) and electron-beam deposition (e-beam) antireflection coatings. (a) Reflectance spectra, (b) coating absorption, and (c) laser-induced damage probability. (Image by SIOM)

Article website:

https://doi.org/10.1016/j.jallcom.2020.157875

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/