To improve the light quality and enhance the luminous efficiency(LE) of YAG:Ce phosphor, a research team from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, successfully fabricated a novel ternary ZrO2-Al2O3-YAG:Ce composite ceramic phosphors recently. The result was published in Journal of the European Ceramic Society in February 2021.

In their experiment, commercial Y2O3, α-Al2O3, CeO2, ZrO2 powders were used as raw materials. The powders were weighted according to the formula and fully mixed. After ball milling in ethanol for 24 h, the slurry was dried at 75 oC and granulated with a 200-mesh sieve. After pressed into disks under uniaxial pressure of 10 MPa, the disks were processed under cold isostatic pressing at 200 MPa. The pressed disks were then heated in a muffle oven at 700 oC for 3 h to remove the organic ingredients. Finally, the phosphor ceramic samples were obtained after sintered at the temperature of 1650 ~1700 oC for 12 h, respectively.

From the microstructure evolution, they found that the addition of ZrO2 can remarkably promote the densification process of samples. From the EDS analysis result, it was discovered that the three phases of ZrO2, Al2O3, and YAG can co-exist with each other independently after sintering although Y in YAG and Zr in ZrO2 can exchange to a certain extent.

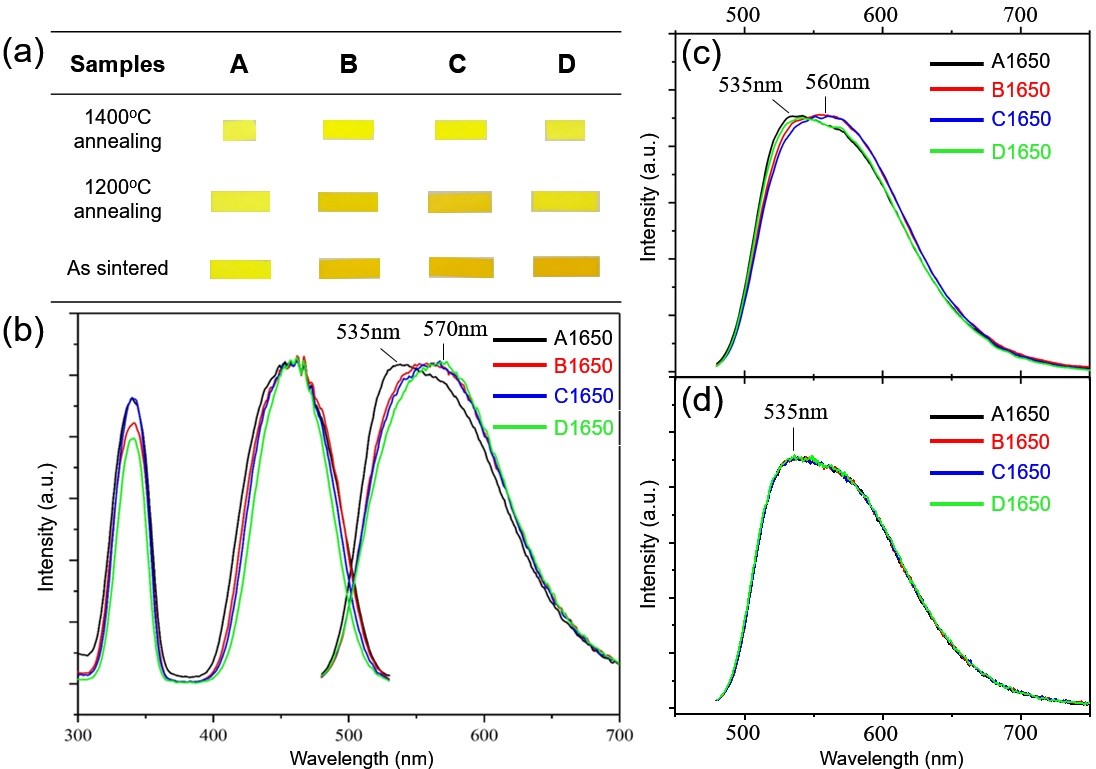

The emission peak of Ce3+ redshifts from 535 nm to 560~ 570 nm with the increasing of ZrO2, which is argued to be related to the non-radiative transition process between the 5d1 level of Ce3+ and oxygen vacancy levels. The w-LED based on B1650 shows a high CRI of 64 and a high LE of 92.36 lm/W, which is greatly enhanced compared to the previous report.

The result has indicated the great application prospect of ZA-YAG:Ce ceramics in warm w-LEDs.

This work was supported by the Innovation Program of Science and Technology Commission of Shanghai Municipality and the International Partnership Program of Chinese Academy of Sciences.

Figure (a) The pictures of ZA-YAG:Ce ceramics of A1650-D1650 as sintered, and after air annealing at 1200 oC and 1400 oC; (b) Normalized PL and PLE spectra of A1650-D1650 as-sintered; (c) Normalized PL spectra of A1650-D1650 after (c) 1200 oC and (d) 1400 oC air annealing. (Image by SIOM)

Article website:

https://doi.org/10.1016/j.jeurceramsoc.2020.10.027