Electron-beam (e-beam) deposited coatings have been widely used in high-power laser systems worldwide due to their relatively high laser-resistance, good spectral uniformity, and the ability to scale to large-aperture.

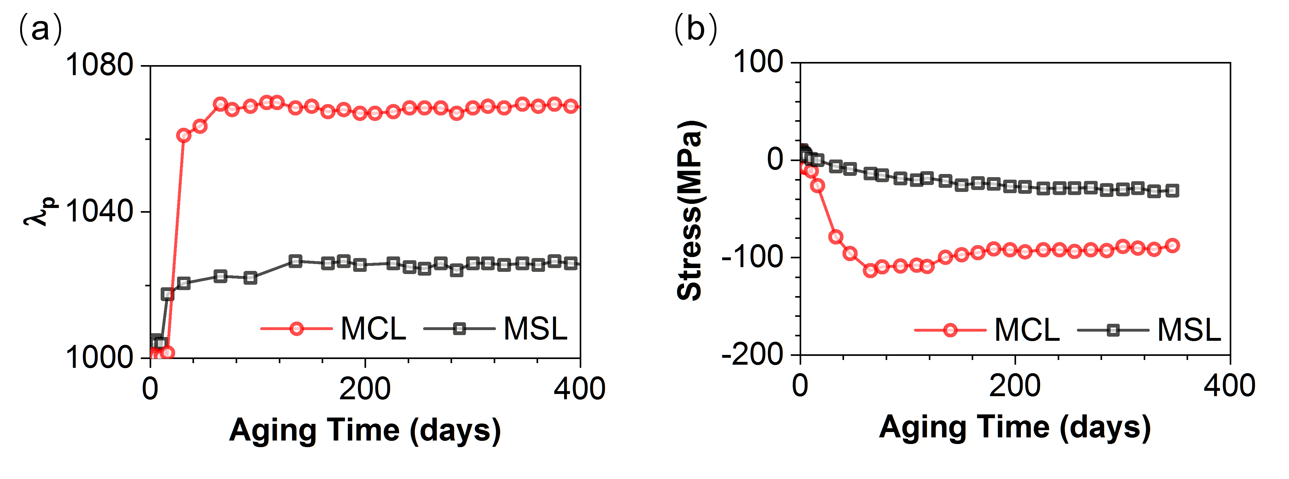

Unfortunately, the porous nature of the e-beam coating allows the absorption and desorption of water, making the coating susceptible to environmental conditions, especially the environmental humidity. Even in a controlled environment, the performance of the e-beam coating can change with increasing aging time. How to obtain low-stress e-beam coatings with long-term stability has not been addressed.

Recently, a research team from the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, proposed a shell layer strategy to achieve a low-stress e-beam coating with significantly improved long-term stability. The work was published in Optical Materials Express 1 November, 2020.

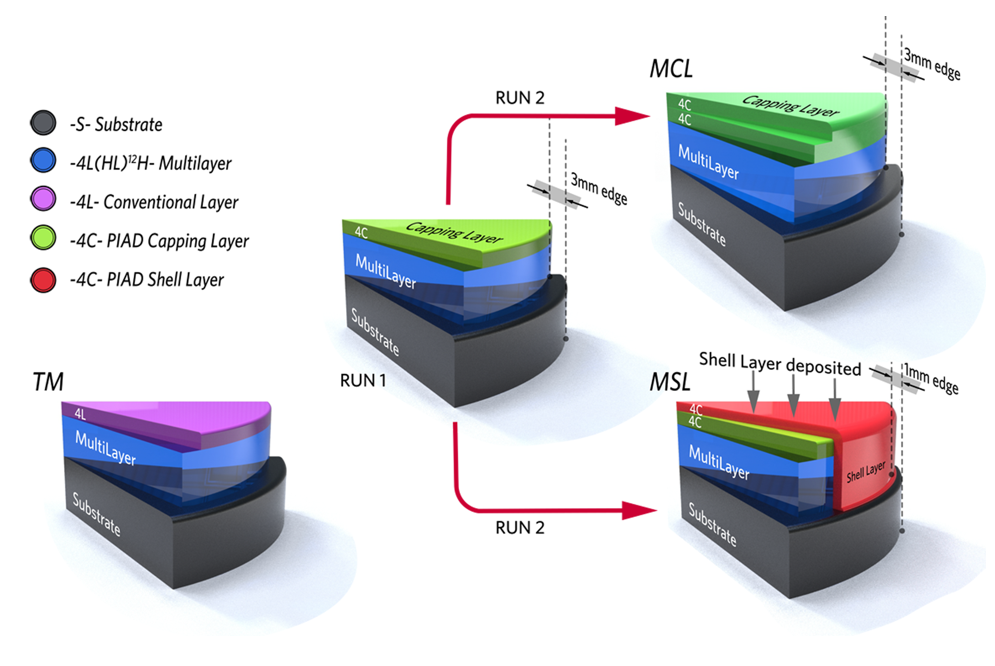

In this work, researchers employed a shell layer deposited by plasma ion-assisted deposition to cover the top surface and sidewall of the e-beam coating. The shell layer strategy can effectively isolate the inner e-beam coating from the ambient humidity, thereby significantly improving the long-term stability and mechanical properties of the e-beam coating.

Meantime, the shell layer strategy of isolating ambient humidity avoids the increase in compressive stress caused by water absorption of the e-beam coating, thereby keeping the entire coating stress at a low level. The shell layer strategy also enables one to evaluate the stress of the coating without water in an atmospheric environment, which is traditionally obtained by performing wave-front measurements in a vacuum environment. The proposed shell layer strategy can be used to address the time- and environment-dependent instability issues of the e-beam coatings for high-power laser applications.

This work was supported by the National Natural Science Foundation of China; Youth Innovation Promotion Association of the Chinese Academy of Sciences; Strategic Priority Research Program of the Chinese Academy of Sciences.

Fig. 1. Schematic diagram of multilayer coatings with and without shell layer. (Image by SIOM)

Fig. 2. Long-term performance of multilayer coatings with and without shell layer. (a) Wavelengths at peak reflectivity versus aging time. (b) Stresses versus aging time. (Image by SIOM)

Article website:

https://www.osapublishing.org/ome/fulltext.cfm?uri=ome-10-11-2738&id=440956

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/