Recently, the research team of Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences has made new progress in the preparation of perovskite quantum dots using glass with low glass transition temperature as a precursor.

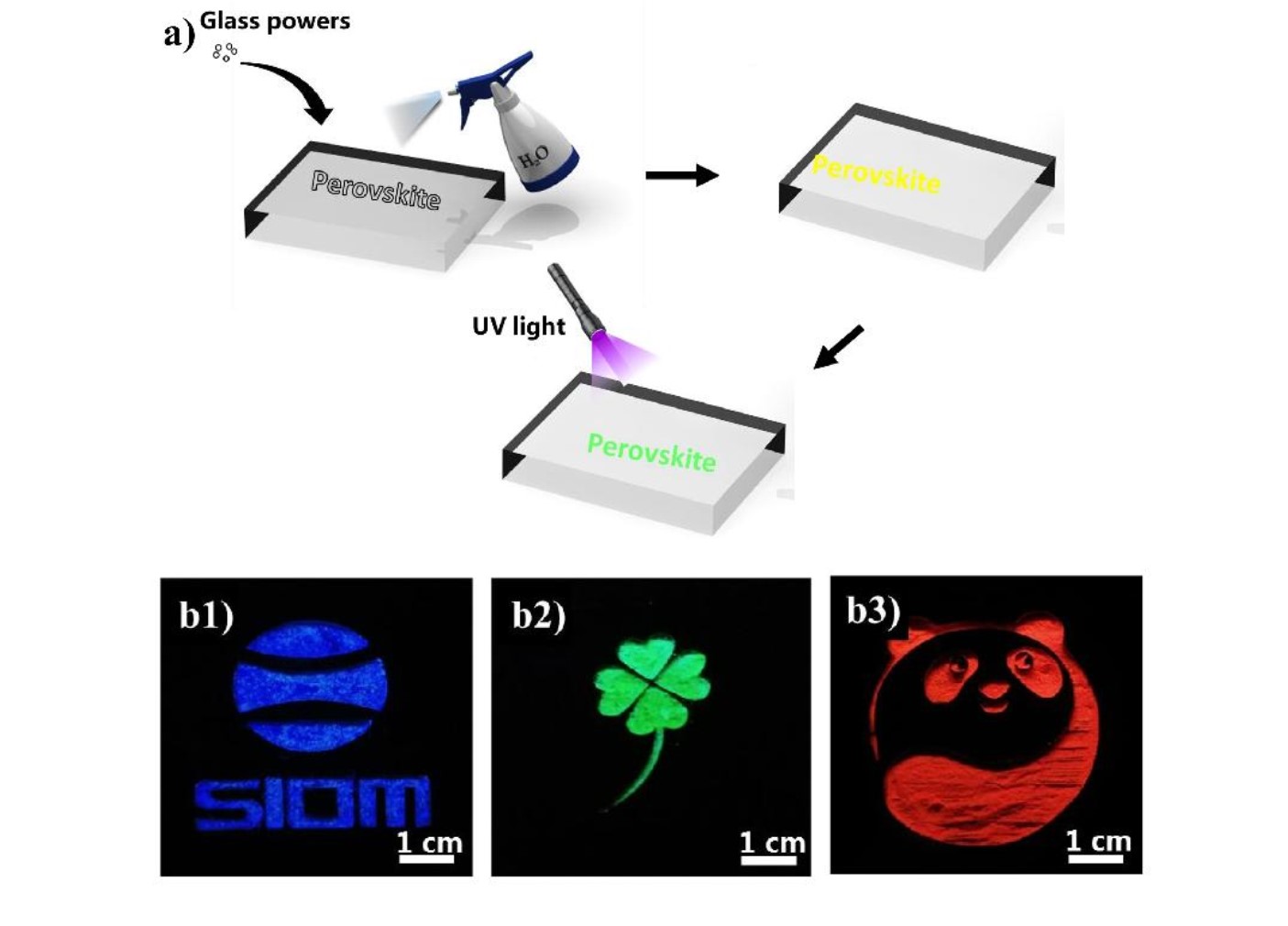

Different from the traditional heat treatment method, the researchers invented a new method for preparing perovskite quantum dots using glass as a precursor. The CsPbX (X=Cl, Br, I) quantum dots were prepared on the glass surface by water induction. The method shows application prospects in the field of anti-counterfeiting. Related research results have been published in the Journal of Alloys and Compounds.

The current severe challenge for cesium halide perovskite quantum dots is still extremely poor stability in the case of polar solvents such as water.

Providing it with a protective layer has always been considered a simple and effective method. Therefore, a heat treatment/pressure induced method for preparing perovskite quantum dot glass ceramics was developed.

In addition to destroying the cesium halide perovskite quantum dots, water also shows a positive side for its formation: inducing crystal formation, controlling the shape and size of the crystal, and increasing the fluorescence quantum yield, but regarding the beneficial effect of water in colloidal quantum dots have never appeared with glass as a precursor.

Therefore, a low-melting tin fluorophosphate glass was used as the basic component to reduce the precursor glass preparation temperature and halogen volatilization; at the same time, a new non-thermally induced phase transition process was explored, using tin fluorophosphate glass is used as a precursor to induce the synthesis of cesium halide perovskite CsPbX3 (X=Cl, Br, I) quantum dots on the surface with water at room temperature. This unique phenomenon has potential applications in the field of anti-counterfeiting.

Related research was supported by the National Natural Science Foundation of China (No. 51872308).

Figure (a) Demonstration application: Patterns produced by depositing the glass powers on a wood substrate after humidifier spray treatment under UV light (λ = 365 nm). (b1) The logo of SIOM. (b2) Clover pattern. (b3) Panda pattern. (Image by SIOM)

Article website:

https://doi.org/10.1016/j.jallcom.2019.152872

Contact:

Mr. Wu Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn