Recently, researchers from the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences have made new progress in the quasi-continuous-wave (QCW) 1064-nm laser annealing of indium tin oxide (ITO) films. The dependence of initial deformations and cracks on the surface of ITO film on the temperature rise induced by QCW laser was discovered. This study has been published in Optical Materials Express (Vol.10, Issue 10, pp. 2394-2405 (2020), DOI: 10.1364/OME.402183).

As one of the most important transparent conductive electrode materials, ITO is widely employed in optoelectronic devices like solar cells, electro-optic switches, liquid-crystal devices, and so on.

Temperature-induced in depositing and post-annealing processes is one of the most important factors that influence the performances of ITO films. An appropriate annealing temperature can improve the crystallinity, surface roughness, and optoelectrical properties of the films.

However, excessive temperature, specifically, a rapid temperature rise induced by laser irradiation, leads to film damages like cracking, melting, evaporation, and ablation. The thermal phenomena suggest potential routes to improve performances of ITO films by optimizing temperatures of laser annealing.

In this study, the research group employed a high-average-power QCW 1064-nm laser to realize a gradual rise of annealing temperature and tailored the temperature distribution of ITO films by designing ITO films with different thickness.

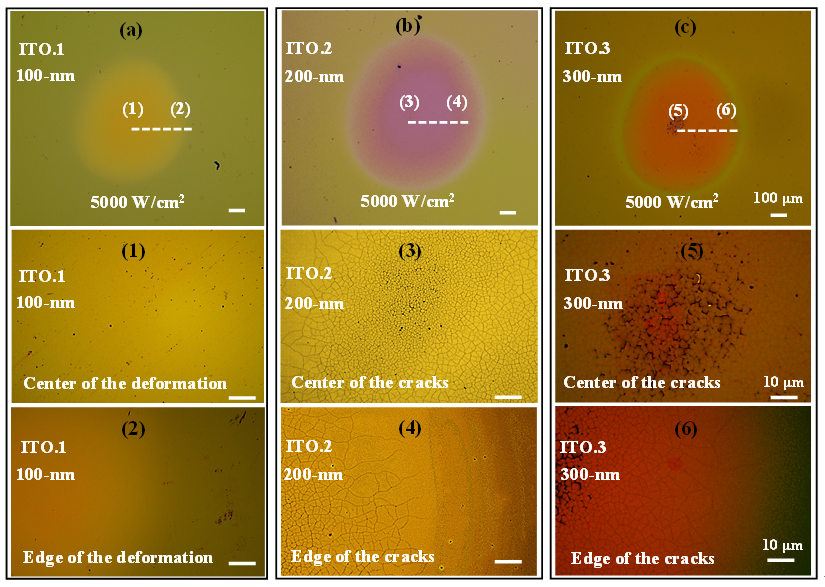

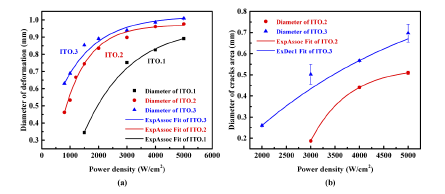

The results show that the initial deformations and cracks will occur if the temperature of the film surface rises to a certain temperature, which is about 520 K and 1250 K, respectively. The sizes of the initial surface deformations (or cracks) are coincidence with the sizes of the regions where the surface temperature is higher than the deformation (or crack) temperature threshold.

This study clarifies the effect and mechanism of QCW laser annealing and provides important guidance for the optimization of the QCW laser annealing process and its application.

This work was supported by the National Natural Science Foundation of China (11874369, U1831211), the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB1603), and the Open Research Fund of State Key Laboratory of Pulsed Power Laser Technology.

Figure 1 Surface morphologies of ITO films with different temperature distribution. (Image by SIOM)

Figure 2 Comparison between the experimental and simulated morphology diameters. (a) The experimental and simulated deformation diameters. (b) The experimental and simulated cracks diameters. (Image by SIOM)

Article website:

https://www.osapublishing.org/ome/abstract.cfm?uri=ome-10-10-2394

Contact:

Mr. Wu Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn