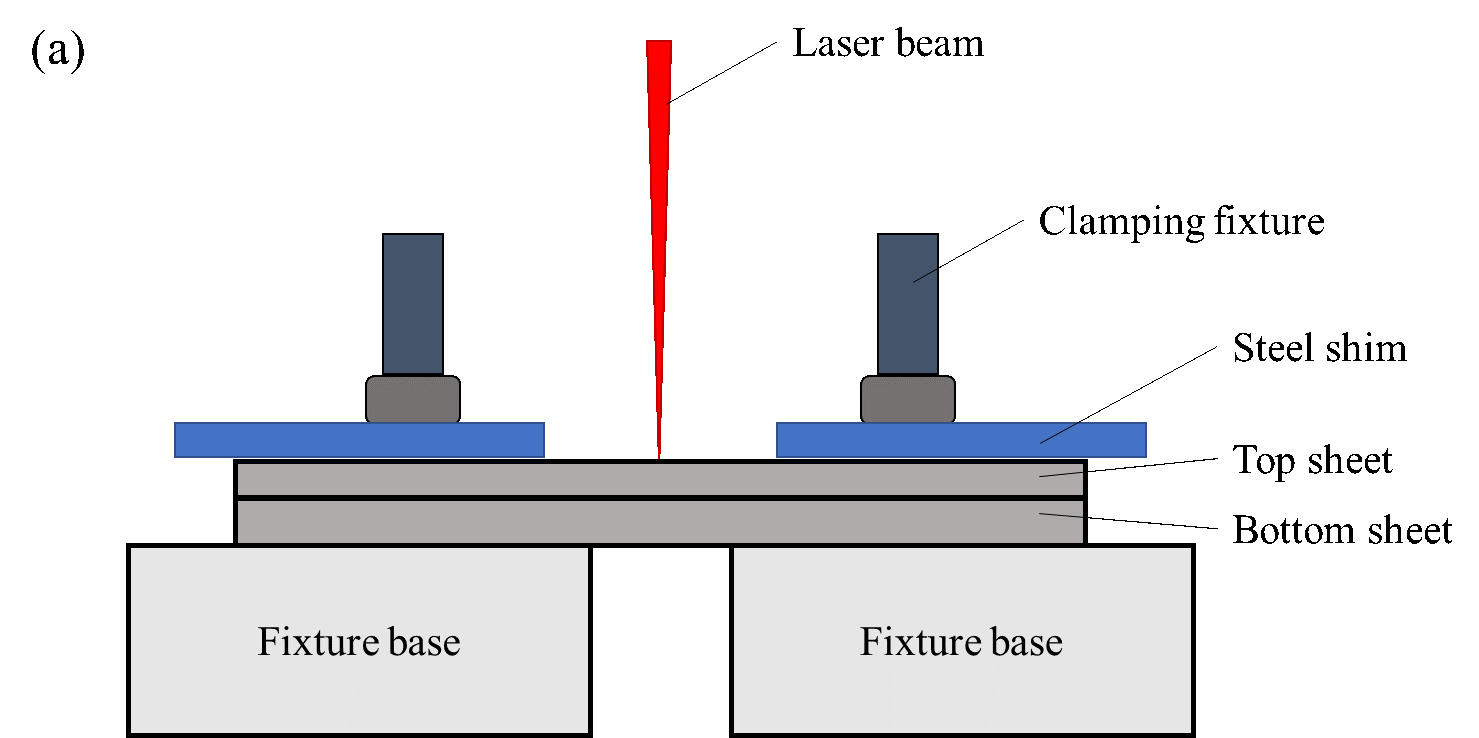

Recently, a research team from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, has proposed an innovative porosity-eliminated laser welding process based on the combination of super-fast welding speed (defined as > 10 m/min) and the oscillation welding path. Related work was published in Journal of Materials Processing Technology December 2020.

Aluminum alloys are widely applied in the automotive, aerospace, transportation industries. Due to the presence of high melting aluminum oxides on the aluminum alloys, the common way to join aluminum alloys heavily depends on mechanical joining methods and arc welding.

The big issue for laser welding of aluminum alloys is the formation of the porosity in the weld zone, which dramatically degrades the joint strength and limits the utilization of laser welding in aluminum alloys.

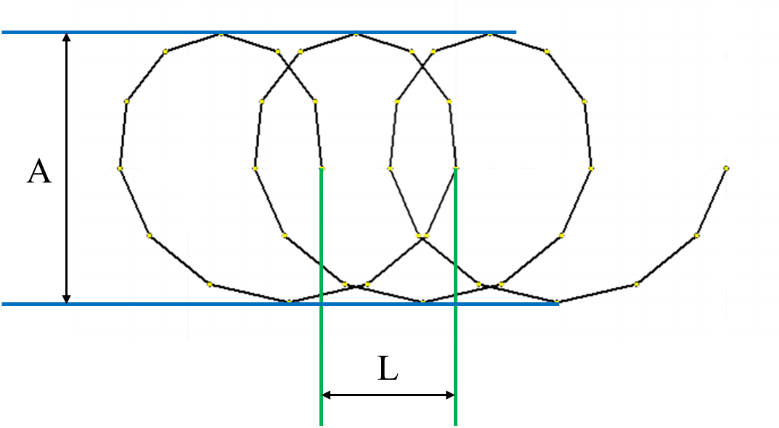

They found that the porosities formation in the weld zone can be dramatically reduced with 43.5 m/min welding speed and the designated oscillation path, compared with the case following the straight welding path and the welding speed of 3.0 m/min. Furthermore, the porosity-free aluminum laser welds were achieved when the oscillation amplitude was larger than the laser beam focal diameter, and the corresponding tensile shear strength was significantly enhanced.

A new laser welding mode that combines the keyhole mode with the conduction mode was proposed to explain the porosity elimination mechanism.

This work was supported by the Chinese Academy of Sciences, Shanghai Municipal Economic and Informatization Commission, Science and Technology Commission of Shanghai Municipality.

Article website:

https://doi.org/10.1016/j.jmatprotec.2020.116826

Contact:

WU Xiufeng

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: xfwu@siom.ac.cn

Web: http://english.siom.cas.cn/