Filamentation occurs when an intense femtosecond laser pulse propagates in optically transparent media such as air. It has found applications from imaging, microfabrication to remote sensing, water condensation, triggering and guiding discharges, in which the radial distribution of laser fluence inside a filament core is crucial. However, direct measurement and control of fluence within filament core (less than 100 μm in diameter) is still a challenge due to its extremely high intensity.

Recently, researchers from Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences demonstrated novel methods to directly measure and successfully control the laser fluence inside a single filament core. The results were published in Optics Express.

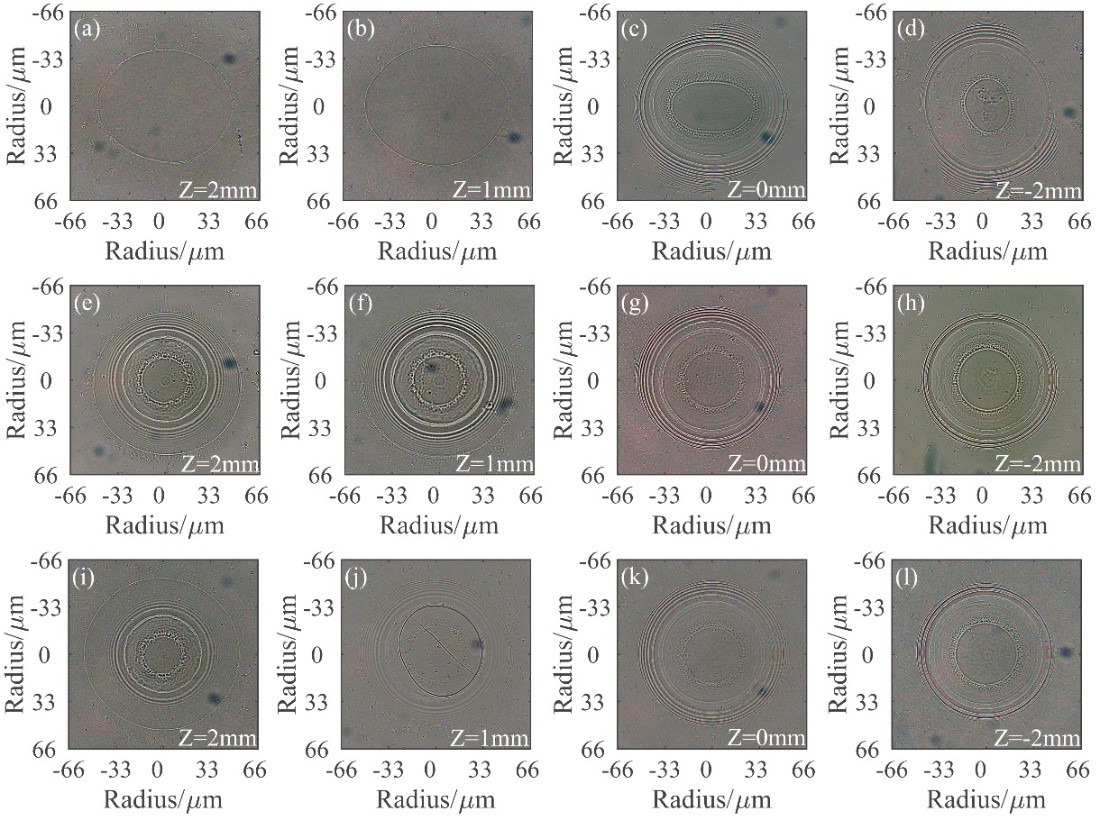

In this work, owing to the filament-fabricated microstructures on materials, the radial fluence distribution across the filament core and its evolution along filament were spatially resolved for the first time. Instead of the traditional circular iris, a stellate iris was introduced to suppress iris diffraction effects.

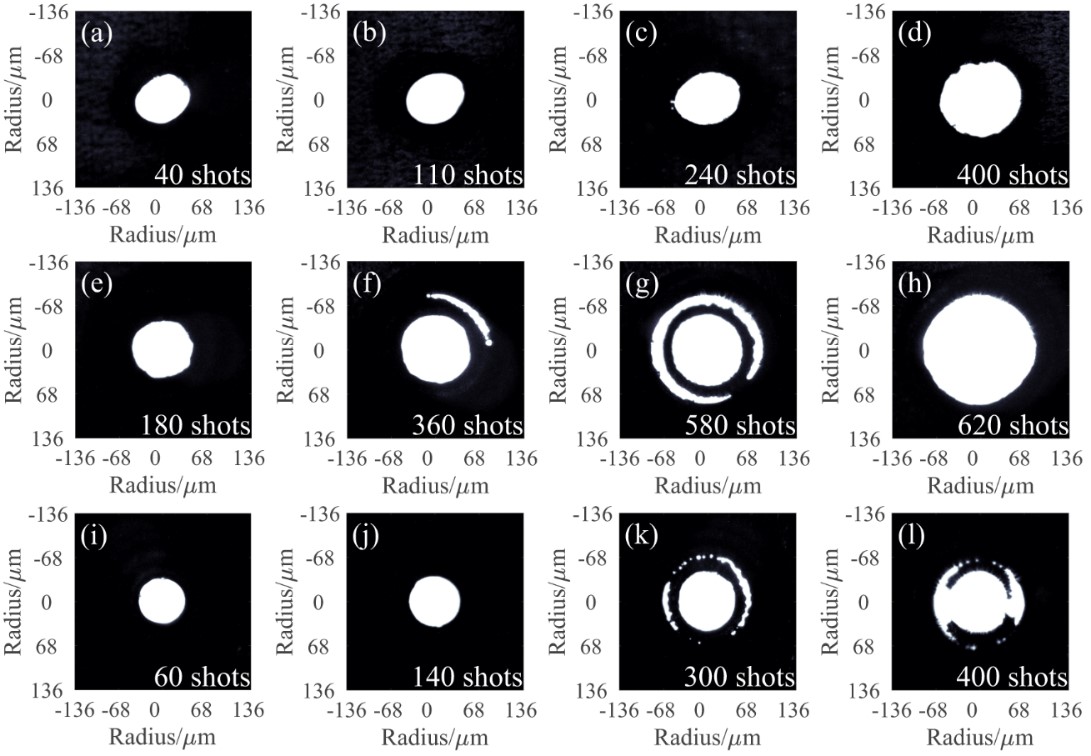

Consequently, a higher laser fluence and denser plasma inside the filament cores were generated, which was further confirmed by the measurement of radial fluence inside filament cores by the filament drilling diaphragms approach. Experimental results are in agreement with numerical simulations obtained by solving the nonlinear Schr?dinger equation.

In addition to new understanding of the filamentation process and its control, this work can also be valuable for filament-based applications, such as imaging microfabrication, secondary radiations and weather modifications of rain making and lightning control.

The study was supported by the Strategic Priority Research Program of the Chinese Academy of Sciences and the International Partnership Program of Chinese Academy of Sciences.

Cross section of single shot filament patterns. (Image by SIOM)

Diaphragms drilled by laser filaments. (Image by SIOM)

Article website:

https://doi.org/10.1364/OE.392827

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn