Laser induced damage in final optics assembly has become one of the bottle neck problems for the development of the high power laser facility. The downstream optics damage caused by the upstream phase defect of micro size is the main reason for the laser induced damage. Therefore, the precise detection and control of the phase defect of the large aperture optical element is very important for improving the load capacity of the high power laser facility. How to realize the high-efficient and precise detection of micro size phase defects on large-diameter (300-400mm) components is a global technical challenge.

Recently, researchers from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences (SIOM, CAS), have reported a novel phase defect detection scheme for large-aperture optics, which combines dark field image and static multi-planar coherent diffraction imaging (MCDI). The results were published in Applied Optics.

The research team proposed a two-step solution to solve the above problems. Firstly, the dark field imaging technology based on the large aperture photon sieve was used to locate the phase defects in the full aperture range, greatly improving the detection efficiency and reducing the system cost.

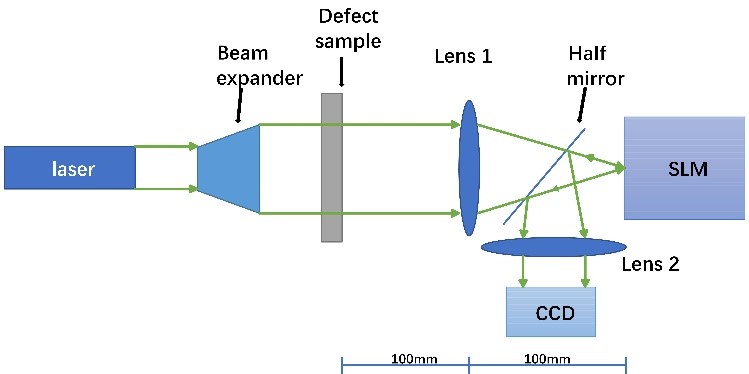

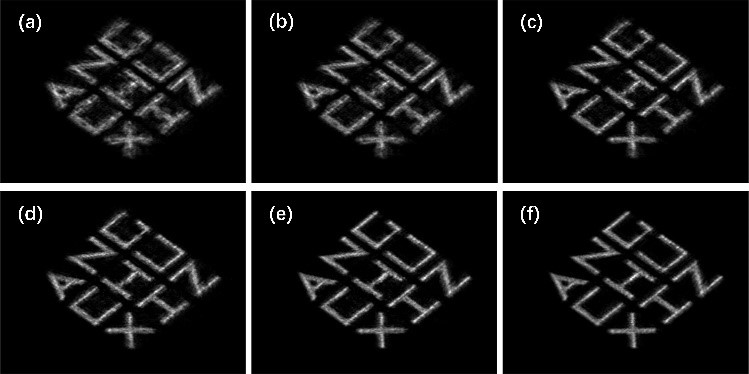

Secondly, the static multi plane coherent diffraction imaging was used to measure the phase defects accurately in a small field of view, and the spatial light modulator was applied as the pancratic lens to avoid the mechanical movement error of the traditional MCDI and improve the system stability.

Compared with the traditional interference measurement method, the proposed optical path of the diffraction measurement system is simple and the defect distribution needn’t to be sparse. The experimental results show that the system resolution is better than 50μm.

This research provides an effective solution for the high-efficiency and high-precision detection of phase defects in large aperture optical elements.

This work is supported by National Natural Science Foundation of China, Natural Science Foundation of Shanghai, Scientific Instrument Developing Project of CAS and Youth Innovation Promotion Association of CAS.

Fig. 1. Precise characterization system based on static multi-planar coherent diffraction imaging with SLM. (Image by SIOM)

Fig. 2 Retrieved field of different iteration times by 4 planes. (Image by SIOM)

Article website:

https://doi.org/10.1364/AO.388185

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn