Traditional online damage detection schemes can directly detect and characterize damage by imaging optical components. However, due to optical resolution, noise, shadows and reflections, the small-size damage points cannot be inspected accurately.

Recently, a research team in Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences (CAS) proposed a three-dimensional damage localization method which was insensitive to the type of damage. This work was published in Optics Express.

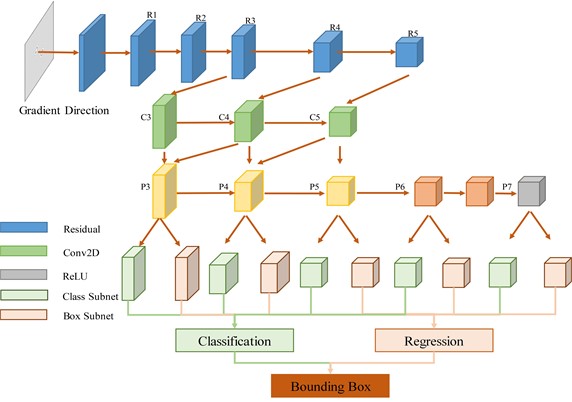

Their research was based on the diffraction rings from optical damage. The axial damage position was obtained by numerically focusing the diffraction ring into the conjugate position (see Fig. 1). A neural network Diffraction-Net (see Fig. 2) was proposed to distinguish the diffraction ring from different surfaces and positions and obtain the lateral position.

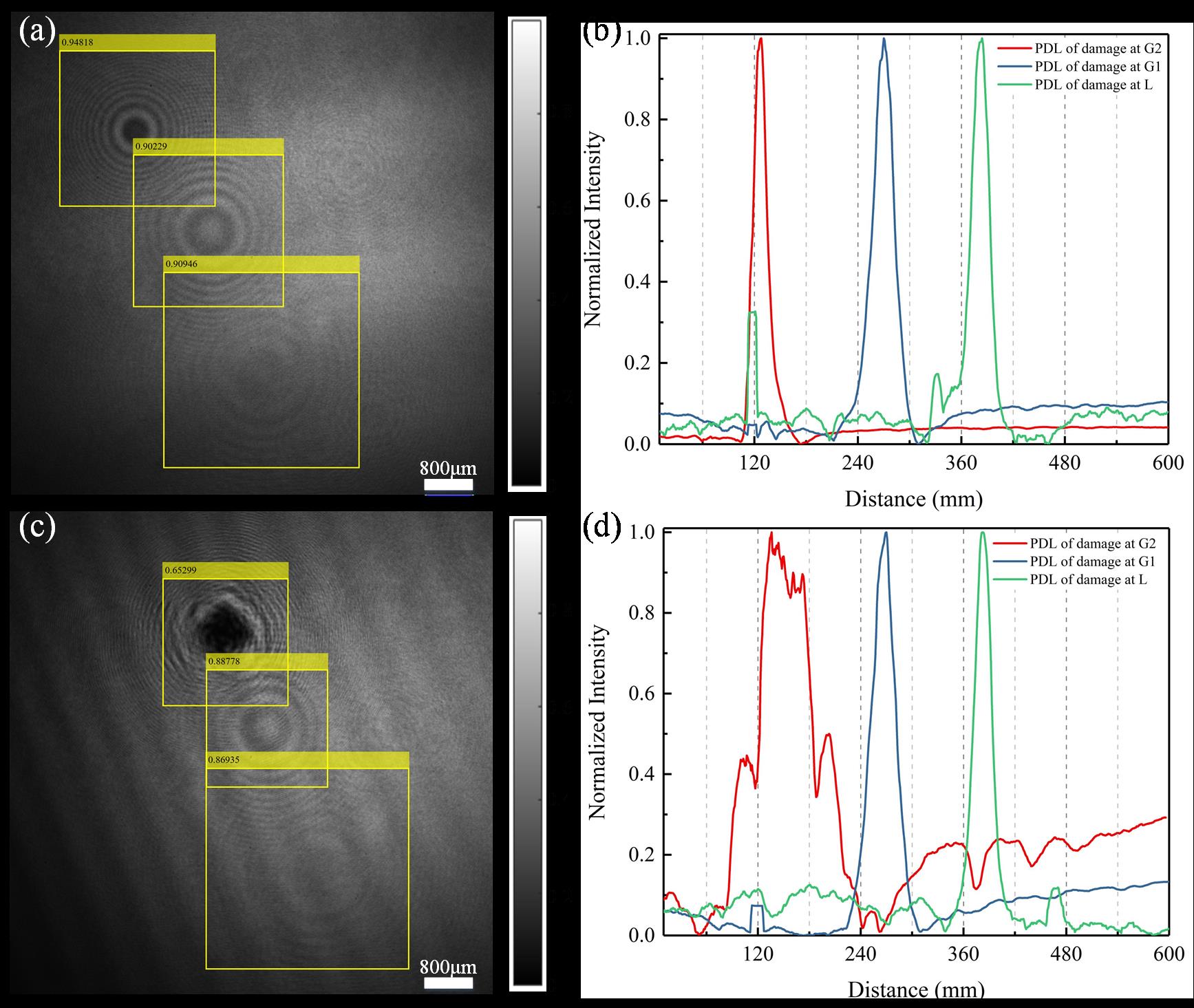

They found that, completely trained by simulative data, diffraction-Net could distinguish the diffraction rings with the overlap rate lager than 61%, which was the best result reported. In the experiments, the proposed method, for the first time, achieved the damage pointing on each surface of cascade slabs using diffraction rings and the smallest inspect damage size was 8μm. The lateral positioning error was less than 38.5μm and the axial positioning error was less than 2.85mm (see Fig. 3).

It should be emphasized that the proposed method has solved the practical inspection problems in the complex optical environment with one intensity recording and thus provides a new way for online damage location in high-power laser system. It will benefit the laser damage control when combining with laser recycle strategy in the future.

This work was supported by the Strategic Priority Research Program of Chinese Academy of Sciences and National Natural Science Foundation of China.

Fig. 1 Schematic diagram of holographic focusing damage positioning. (Image by SIOM)

Fig. 2 The schematic of Diffraction-Net. (Image by SIOM)

Fig. 3 Cascade medium positioning result. (Image by SIOM)

Article website:

https://doi.org/10.1364/OE.387987

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn