Based on magneto-optic materials, Faraday isolators (FIs) are a kind of non-reciprocal devices that play important roles in laser systems to ensure one-way light propagation, protect laser sources, and stabilize the performance of output lasers. As a very promising candidate for the next generation magneto-optic materials used in high power FIs, Tb3Al5O12 (TAG) ceramic is, however, suffering from the optical scattering of the grain boundaries and residual pores formed in sintering process.

Recently, a research team from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Science (SIOM, CAS), for the first time, successfully fabricated highly transparent TAG ceramics through ZrO2-doping, which also revealed a promising approach to minimize the optical scattering in other laser ceramics. The result was published in Scripta Materialia.

In previous work, they used ZrO2 as the sintering aid in the solid state reaction of TAG ceramics and found that it could largely promote the transmittance of TAG ceramics to 82.04%, which accompanied the exaggerated grain growth of the samples. But the specific mechanism still remained unclear.

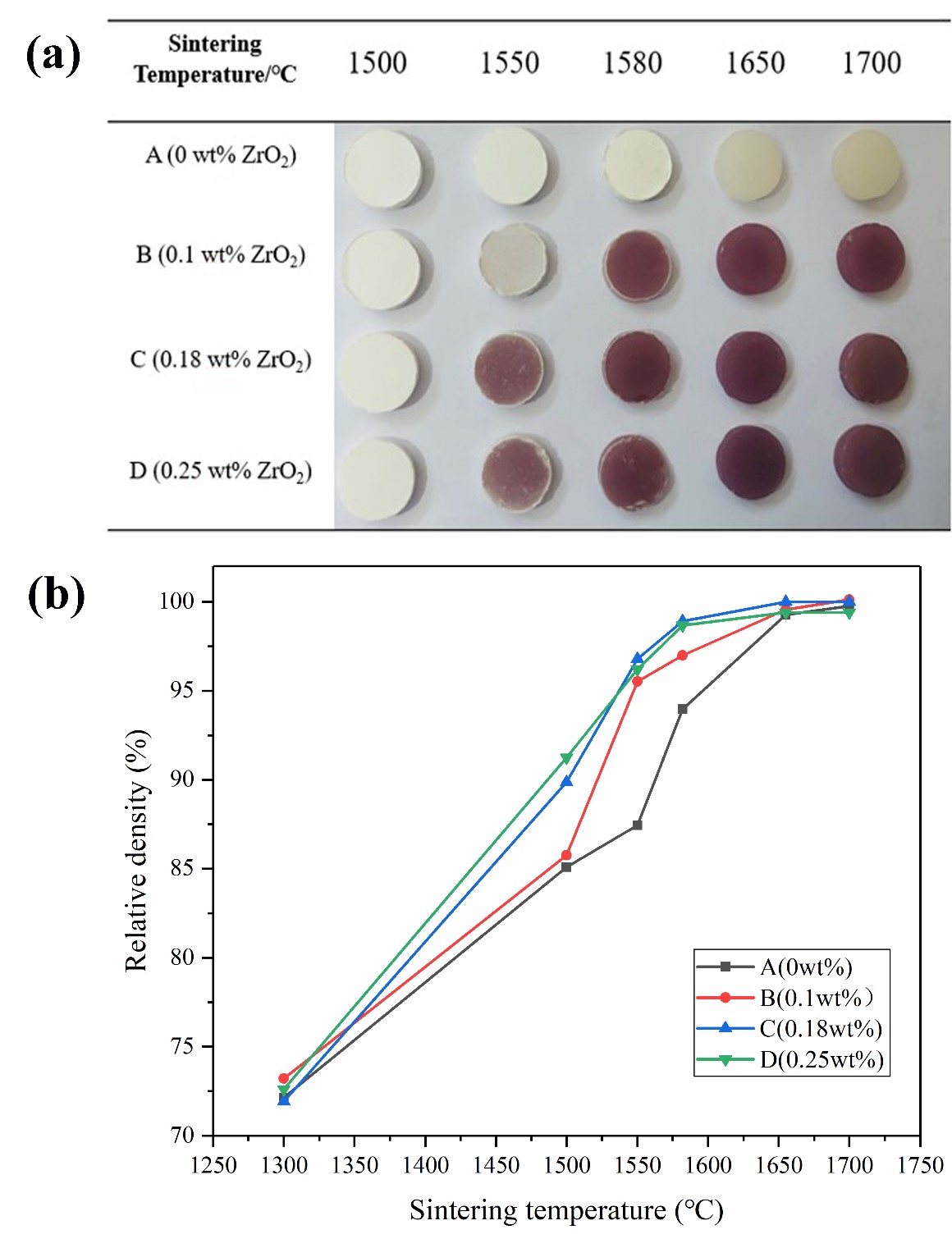

In their newest report, they investigated the effect of ZrO2-doping on the microstructure evolution and phase change of TAG ceramics systematically. The samples with different amount of ZrO2-doping were vacuum sintered at a wide range of temperature from 1200 °C to 1700 °C to explore the changing microstructure and phase composition in the sintering process. Apart from the transformation of Zr4+–Zr3+, a novel phenomenon was discovered in the final stage of sintering that a second phase of ZrO2 was discharged to the surface of samples at the sintering temperature higher than 1550 °C, which was accompanied with a largely promoted grain growth at the same time.

The discharge behavior is considered to contribute to the enhanced optical quality of TAG ceramics for the decreasing residual impurity in grain boundaries. The discharge of ZrO2 sintering aid has also revealed a new possible approach to obtain high quality transparent ceramics with extreme low scattering loss for the reduction or avoidance of residual impurities brought by additives.

Fig. (a) A picture of Zr:TAG ceramics sintered at different temperature between 1500 and 1700 °C for 12 h;

(b) the relative density changes of samples sintered between 1300 and 1700 °C. (Image by SIOM)

Article website:

https://doi.org/10.1016/j.scriptamat.2019.09.011

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn