In the field of ultra-precision manufacturing, the mid-spatial-frequency (MSF) error can severely affect the performance of the optical elements, but it is rather difficult to quantitatively predict the MSF error distribution.

Recently, the research team in Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, has established the piecewise-path convolution (PPC) model and found the generation mechanism and quantitative prediction method of the MSF error. The work was published in Optics Express.

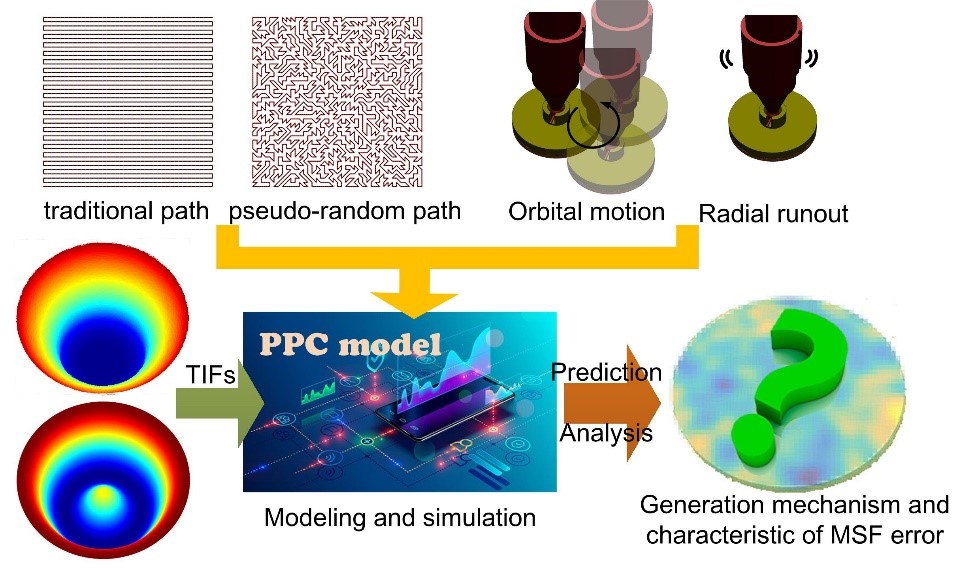

In this work, the MSF error distribution could be accurately predicted through this method. Besides, the mechanism of reducing MSF error by path type and TIF was successfully explained mathematically by using the theory; and the simulation results showed that the orbital motion or the radial runout could also introduce non-negligible MSF error. This method is of essential for the MSF error prediction and convergence.

Moreover, two selection formulae of path type, TIF and polishing parameters, were provided for low MSF error polishing, which gave the theoretical guidance for the parameter selection in deterministic polishing. The cut-off frequency fc formula was defined for the selection of the path type and TIF, and the MSF error could be eliminated by ensuring the fc lower than the range of MSF. Researchers could achieve the requirement through non-periodic paths, regular paths with smaller scanning interval and larger tool / smoother TIF. For contact tool (i.e. small-tool, bonnet tool, etc.), the TIF smoothness could be improved by smoothing the contact pressure distribution; Also, the constraints on the polishing parameters (feed rate, angular velocity, etc.) to reduce the MSF error were caused by the orbital motion or the radial runout.

The PPC method has the ability to quantitatively predict the MSF error of most polishing tools and the selection formulae are instructive for the setting of processing parameters for low MSF error polishing.

This work were supported by the Key Projects of the Joint Fund for Astronomy of National Natural Science Funding of China and Outstanding Member of Youth Innovation Promotion Association of the Chinese Academy of Sciences.

Schematic diagram of PPC model analysis method. (Image by SIOM)

Schematic diagram of multi-layer tools smoothing effect. (Image by SIOM)

Article website:

https://www.osapublishing.org/oe/abstract.cfm?uri=oe-28-6-8959&origin=search

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn