DKDP (KDxH2-xPO4) crystal is the best tripler suitable for inertial confinement fusion (ICF) facility for its effective suppression of stimulated Raman scattering. For the ‘point-seed’ rapidly grown KDP-type crystals, all prismatic faces and pyramidal faces grow under high supersaturated solutions, forming the so-called pyramid-prism (PY-PR) boundary which is detrimental to efficient frequency tripling and phase matching.

More recently, using the rapid growth method, a cuboid DKDP crystal is rapidly grown. Without a pyramidal sector, the cuboid DKDP crystal shows advantages of crystal shape, good deuterium homogeneity, crystalline quality, transmission and laser-induced damage performance. However, since the prismatic sector is sensitive to impurity ions compared to the pyramidal sector, it is necessary to find suitable post-processing means to further improve the crystal quality of the cuboid DKDP crystal.

Thermal annealing is an effective method to improve the quality of KDP-type crystals. Recently, effect of thermal annealing on the cuboid DKDP crystal were evaluated by researchers from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences. Their study was published in Journal of Alloys and Compounds.

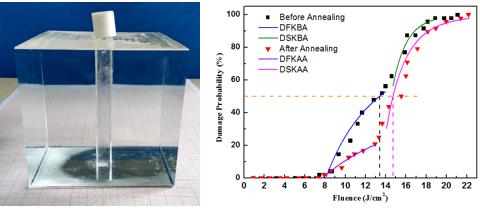

In their experiment, after annealing in silicone oil, crystalline quality, transmission, weak absorption, and LID performance of the samples cutting from the cuboid DKDP crystal were investigated.

They found that, through thermal annealing, the symmetry of the HRXRD of the X-cut sample was much better, indicating that the uniformity of the cuboid crystal was improved. The transmittance of annealed THG-oriented sample was obviously higher than the as-grown THG-oriented sample from 400 - 300 nm. At 355 nm, the transmittance of the THG-oriented sample increased from 80.4% to 87.9% after thermal annealing.

The LID performance of the THG-oriented sample was also improved through thermal annealing, and the fluences corresponding to 50% probability of LID was increased from 13.4 to 14.8 J/cm2 (@3ns, 355nm). Also, the density of the defect with low LID threshold decreased by two-thirds. This was probably because the structure of some defects could be optimized under thermal annealing, making better the crystalline quality, transmission, weak absorption, and LID performance of the cuboid DKDP crystal.

The above results demonstrate that thermal annealing is an effective means to further improve the quality of the cuboid DKDP crystal.

The rapidly grown cuboid DKDP crystal and the LID performance of the THG-oriented samples. (Image by SIOM)

Article website:

https://www.sciencedirect.com/science/article/pii/S0925838819340587

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn