Transparent ceramics that possess good mechanical performance, exhibit large in size, and contain excellent optical properties are promising high-power laser materials. Currently, rare-earth doped SrF2 transparent ceramics have been fabricated by the hot-pressed method. To obtain desired ceramic samples, a single-crystal ceramization (SCC) technique was developed by combining hot-formed and hot-pressed. Notably, the deep plastic deformation treatment will reduce the laser performance of ceramics to a certain extent, which could be attributed to fluorescence quenching originating from re-clustering of partial Nd3+ ions. However, the SCC process is different from hot-formed, which is composed of deep plastic deformation, rapid cooling, and hot-pressing sintering. Therefore, determining whether there is re-clustering of Nd3+ ions during SCC, and how to eliminate it becomes significant.

Recently, a research team led by Professor ZHANG Long from Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences has developed a simple thermal drive induced grains regrowth (TDIGR) treatment technique and solved Nd3+ re-clustering encountered into Nd3+, Gd3+-codoped SrF2 laser ceramic. Their study was published in Journal of the American Ceramic Society.

In the experiment, they discovered that the Nd3+ re-clustering phenomenon existed during the SCC process by comparing the fluorescent properties of Nd3+,Gd3+-codoped SrF2 ceramic. The grain boundaries were the result of the ions reaching a new equilibrium state under high temperature and high pressure. They thought that the re-clustering of Nd3+ ions were most likely to occur at the grain boundaries. The re-clustering of Nd3+ ions were expected to be relieved via the movement of grain boundaries.

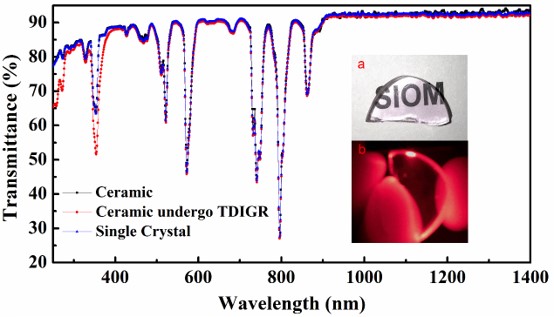

Following the expectation, they heat-treated ceramic samples at 800 °C for 2 h in a nitrogen atmosphere and successfully realized the relocation of the grain boundaries. Meanwhile, the absorption coefficient, fluorescence emission intensity, and fluorescence lifetime have significantly improved during the TDIGR treatment, which was similar to the single crystal. The experimental results demonstrated that the TDIGR could effectively address the re-clustering of Nd3+ ions issue during SCC.

Furthermore, the transmittance of ceramic was hardly affected by the TDIGR treatment. Therefore, the combination of SCC and TDIGR will further promote development of Nd3+, B3+-codoped MF2 ceramics.

In-line transmittance spectra of the Nd3+,Gd3+-codoped SrF2 single crystals, ceramic before and after TDIGR treatment (Image by SIOM).

Article website:

https://doi.org/10.1111/jace.16945

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn