In 2008, Nishiura et al. reported that the Ce:YAG transparent ceramics are suitable for white LED. Since then, the investigation of Ce:YAG transparent ceramics have been broadly studied. However, the PL spectra of Ce:YAG transparent ceramics lacks red component, which results in a highly correlated color temperature (CCT) and a low color-rendering index.

Recently, a research team from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, for the first time, successfully prepared the composite Al2O3-YMASG ceramic phosphors by a vacuum sintering technique. The result was published in Optics Letters.

In previous experiment, they tried to dope Mg2+-Si4+ pairs in Ce:YAG ceramic phosphors, but its luminous efficiency was low (36 lm/W). Therefore, researchers introduced the Al2O3 as second phase to improve the luminous efficiency.

They found that, with the nominal composition of 10 wt% Al2O3, the impurity phase Y4MgSi3O13 associated with higher doping concentration of Mg2+-Si4+ co-doped in Ce:YAG disappeared. Also, with the nominal composition of 30 wt% -50 wt% Al2O3, the composite Al2O3-YMASG ceramic phosphors was obtained.

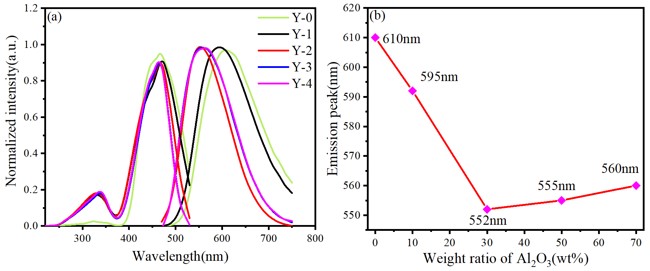

Furthermore, the emission wavelength of Ce3+ could be adjusted from 610 to 552 nm through changing the weight ratio of Al2O3 from 0 wt% to 30 wt% which presents an easy method to modify the emission wavelength of Ce:YMASG.

That the luminous efficacy of samples increases from 35 lm/W to 63 lm/W with the weight ratio increase of Al2O3 from 0 to 30 wt% indicates the introduction of Al2O3 can effectively improve the luminous efficacy and may contribute to Ce:YAG’s application in door and medical lighting.

Fig. The normalized photoluminescence spectra of samples (a) and the emission peak against the weight ratio of Al2O3. (Image by SIOM)

Article website:

https://www.osapublishing.org/ol/abstract.cfm?uri=ol-44-19-4845

Contact:

Mr. CAO Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn