Yb3+/Al3+/P5+ co-doped silica fibers have attracted considerable attention in high-power fiber laser. However, the fiber preform undergoes a series of thermal procedures during the drawing process, leading to significant changes in the network structure and the laser performance of the fiber.

Numerous experimental studies have been conducted on the structural relaxation, which can be affected by the composition or impurities, thermal history, sample size, and air humidity. Until now, no research has been reported to directly disclose the connection between the properties and glass structure of rare-earth ion doped silica glass during the thermal annealing process.

A research team of Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences (CAS) has developed a direct linkage between the evolution of short-range ordered structure and the properties of Yb3+/Al3+/P5+ co-doped silica glasses during the thermal annealing procedure. The work was published in Journal of Non-Crystalline Solids.

In their research, the homogeneous 89.9SiO2-4Al2O3-6P2O5–0.1Yb2O3/Eu2O3 (in mol%) glasses were prepared via a sol-gel method and subsequently vacuum sintered at high temperature, and then they were annealed at 850 °C for 15 and 75 h. Eu3+-doped glass was prepared as an indicator of the site symmetry of Yb3+ ions in glass.

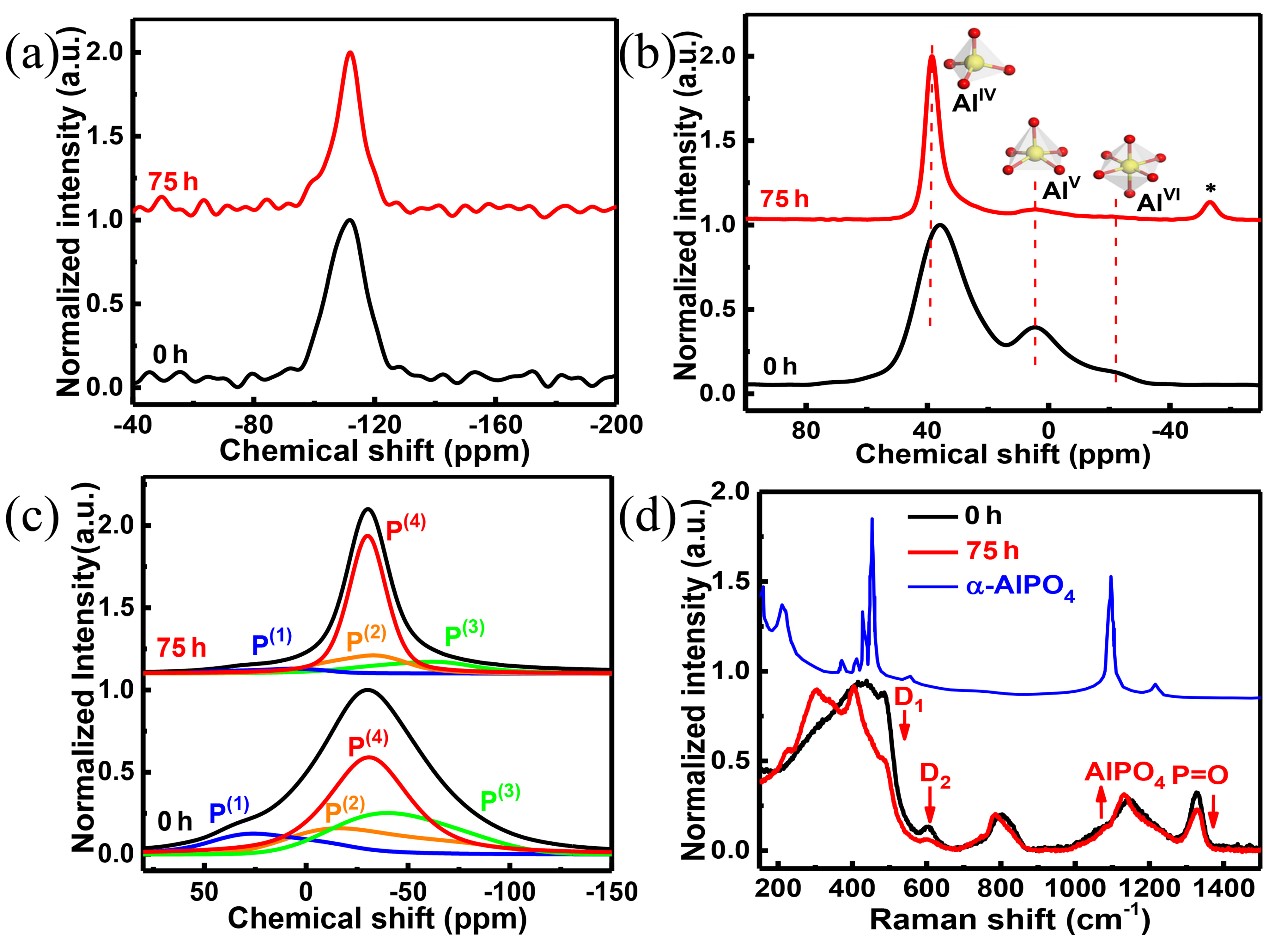

The increase of AlPO4 units at the expense of AlV, AlVI and P(3) groups and the decrement in the four- and three-membered rings accounted for the decrease of density and refractive index during the annealing process. Moreover, the decrement in the absorption and emission cross sections of Yb3+ ions was owing to the reduction in the asymmetry degree of Yb3+ ligands.

This research can provide important reference information for the optimization of spectral properties during the fabrication of ytterbium doped silica fibers.

This work was supported by the National Key Research and Development Program of China.

Characterization of glass network structures of Yb3+/Al3+/P5+ co-doped silica glass before and after thermal annealing.

Article website: https://www.sciencedirect.com/science/article/pii/S002230931930434X

Contact:

Mr. Cao Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn