The dispersive mirror (DM) has the advantages of high reflectivity and precise control of dispersion compensation and is one of the important dispersion compensation components in the ultra-short pulse laser system. With the development of ultra-short pulse technology, the DM is required to have a wide working bandwidth and a larger dispersion compensation amount. Since the bandwidth, dispersion and dispersion oscillation of the DM have mutual constraints, the increase of bandwidth and dispersion will inevitably lead to the increase of group delay dispersion (GDD) oscillations, which will seriously affect the pulse output quality in practical applications.

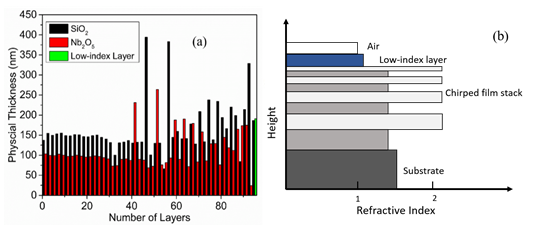

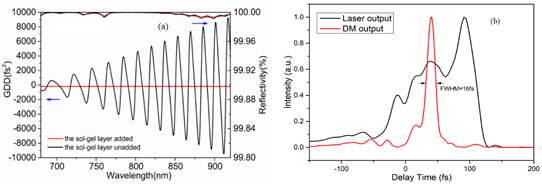

Recently, the Thin Film Optics Laboratory of Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, has made progress in the study of low-ripple dispersive mirror. Based on the design idea of surface anti-reflection film impedance matching, the research group designed, fabricated and applied a low-ripple DM with a SiO2 sculptured layer. The low-ripple DM has a multilayer structure consisting of aSiO2sculptured layer with a low refractive index of ~1.09 fabricated by glancing-angle deposition (GLAD) on top of a conventional chirped film stack fabricated by dual-ion beam sputtering. The group delay dispersion (GDD) of the DM is -200 fs2 in the spectral range from 680 to 920 nm. The GDD oscillations of the DM could be significantly reduced compared to the conventional chirped film stack without the SiO2 sculptured layer while maintaining a large GDD of several hundred femtoseconds square and a wide dispersion bandwidth.

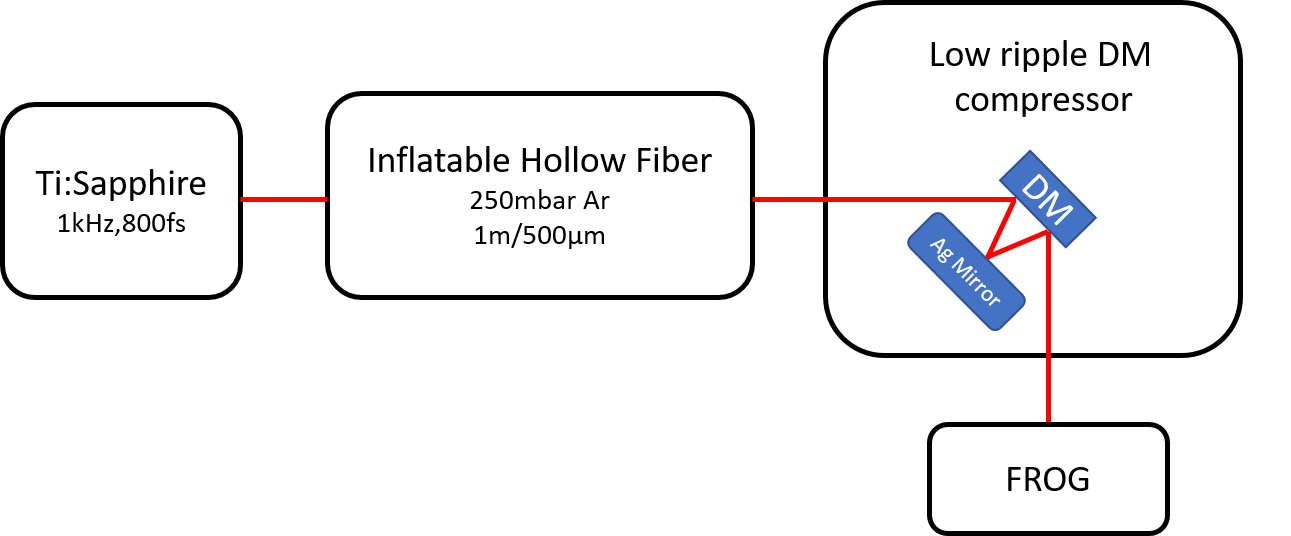

In their experiment, the SiO2 sculptured layer is deposited by glancing-angle deposition, and the refractive index can be reduced to 1.09 (@800 nm), which can better match the air medium, thereby reducing the GDD oscillation of the DM. The interlaced chirped film stack of Nb2O5/ SiO2 high and low refractive index materials was prepared by ion beam sputtering process, and the sculptured SiO2 layer was deposited on this basis. The fabricated single low-ripple DM is applied to the Ti:Sapphire laser system. A total of the DM for an angle of incidence of ~5° is utilized to compensate the GDD of -400 fs2 with 2 reflections, which can compress the 100fs laser pulse to 16fs. For the first time, a single DM with a SiO2 sculptured layer has been successfully applied in a fiber chirped system without being used in DM-pair, which can realize the compression of laser pulses to 16fs.

The results, entitled "Design, fabrication and application of the dispersive mirrors with a SiO2 sculptured layer", were published in Optical Materials Express on April 1, 2018.

The research was funded by the National Natural Science Foundation of China and the China Academy of Engineering Physics (U1630140), the Chinese Academy of Sciences Youth Innovation Promotion Association (2017289), and the Chinese Academy of Sciences' Strategic Pilot Science and Technology Special (B) (XDB1603).

Figure.1. Layer-thickness profile of the optimum DM design (a). The schematic refractive index profile of the DM (b).

Figure.2. Schematic layout of the fiber system with the DM compressor.

Figure.3. Theoretical reflectance and GDD of the designed DM before and after the top low-index layer is added (a). Black and red curves represent the theoretical effective GDD and reflectance before and after the top low-index layer is added, respectively. FROG trace of pulses compressed via 2 bounces of the DM (b).

(Image by SIOM)

Contact:

Mr. Cao Yong

General Administrative Office

Shanghai Institute of Optics and Fine Mechanics, CAS

Email: caoyong@siom.ac.cn