Polycrystalline transparent ceramics have drawn considerable attention for use in infrared windows and domes because of their favorable mechanical and optical properties. However, increased mechanical strength, improved thermal shock resistance and lower emissivity are needed to develop faster, more accurate advanced hypersonic missiles.

Recently, researchers at Shanghai Institute of Optics and Fines Mechanics (SIOM) of Chinese Academy of Sciences propose a citrate–nitrate combustion method, based on the redox reaction between citric acid and nitrate, which used to synthe-size composite Y2O3–MgO nanopowders with average particle sizes of 17 nm. The c/n molar ratio crucially influenced the redox process and the characteristics of the prepared powders. When the c/n molar ratio exceeded the stoichiometric value of 0.28, the reaction rate increased and the amount of organic com-pounds in the Y2O3–MgO nanopowders significantly decreased. For the final nanocomposites, which were achieved by HIP sin-tering the nanopowders, increasing the c/n molar ratio from 0.17 to 0.34 decreased the absorption peaks at approximately 1410 and 1511 cm?1 caused by stretching vibration of carbon-ate groups. Excellent average IR transmittance close to 83% in the 4000–1667 cm?1 (2.5–6 μm) region was obtained when the c/n molar ratio was 0.28 and 0.34.

The study was published in Journal of the European Ceramic Society.

(http://www.sciencedirect.com/science/article/pii/S0955221917302996?via%3Dihub)

This work was supported by the National Youth Natural Science Foundation of China, and the China Scholarship Council.

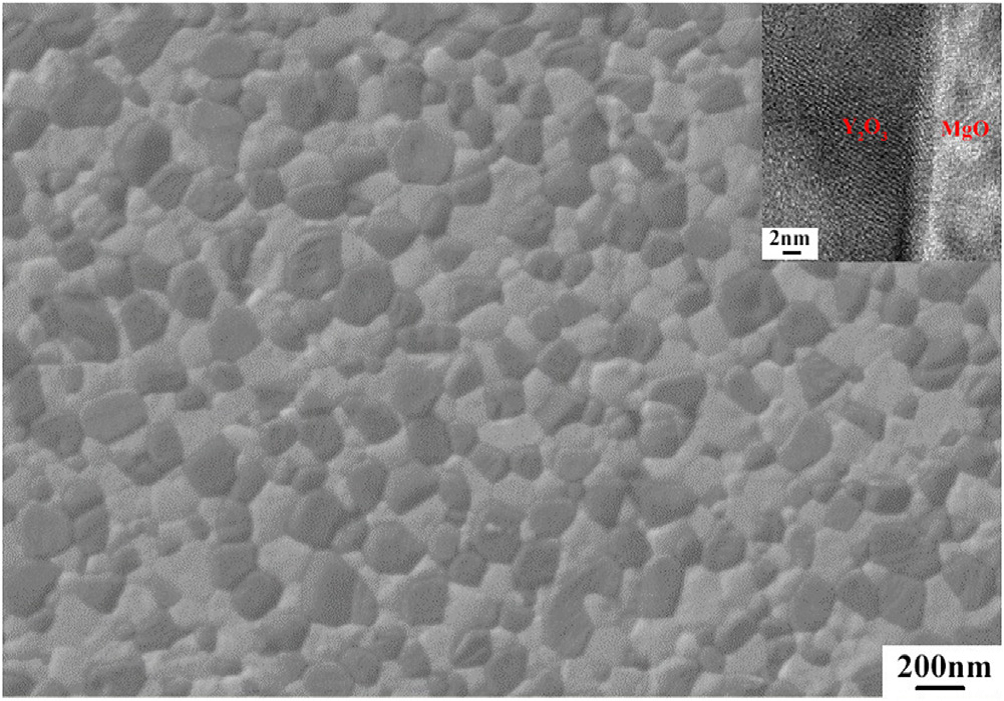

Fig. SEM image of the microstructure and phase distribution of the Y2O3–MgO nanocomposite. Inset: a super-high-resolution TEM image of a grain boundary.

Contact:

Xie Junxi

Shanghai Institute of Optics and Fine Mechanics

E-mail: xiejunxi1005@sina.cn