In whispering-gallery-mode (WGM) microresonators, the total internal reflection along the smooth circular peripheries can lead to high quality (Q) factors and small volumes (V) for inducing dramatic enhancement of light fields. Dielectric crystalline WGM resonators have shown great promise as the next generation nonlinear sources of both classical and nonclassical ligh. In particular, as an important ferroelectric nonlinear crystalline material, lithium niobate (LN) crystal has received significant attention because of its high second order nonlinear and electro-optic coefficients. However, owing to the technical difficulties related to the material growth and the lithographic fabrication on LN substrate, high-Q LN resonators are now typically realized using mechanical polishing whose sizes are limited to millimeter-scale. Realization of high-Q on-chip sub-millimeter LN resonators remains a challenge.

Dr.LIN jintian,under the supervision of Prof. CHENG Ya from Shanghai Institute of Optics and Fines Mechanics (SIOM/China) reported on fabrication of high-Q lithium niobate (LN) whispering-gallery-mode (WGM) microresonators suspended on silica pedestals by femtosecond laser direct writing followed by focused ion beam (FIB) milling.

They established a new technique to fabricate on-chip high-Q sub-millimeter LN microresonators. They fabricated the microresonator on an LN thin film which is formed by bonding an ion-sliced LN thin film onto a LN substrate with a sandwiched silica layer.Using a fiber taper coupling measurement, we determine that the Q factor of a LN microdisk with a diameter of 82 μm can reach ~2.5 × 105. It should be noticed that for sub- 100 μm-diameter LN microresonators, it is very difficult to achieve a Q-factor higher than 105, to the best of our knowledge. Our technique opens the new route for fabricating novel crystalline microresonators for on-chip photonics applications.

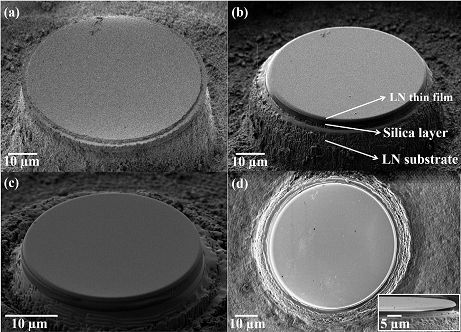

Figure (a) SEM image of a cylindrical post formed after femtosecond laser ablation; (b) and (c) SEM images of two cylindrical posts with diameters of 55 mm and 33 mm, respectively, after the FIB milling; (d) SEM image (top view) of the 55-mm diameter microresonator after the chemical etching and annealing. Inset in (d): side view of the microresonator, showing the freestanding edge of the LN microresonator.

This study was published on Scientific Reports on Jan.28, 2015.[ http://www.nature.com/srep/2015/150128/srep08072/full/srep08072.html. The work is supported by National Basic Research Program of China, NSFC, and the Fundamental Research Funds for the Central Universities.

Home | About SIOM | Newsroom | International | Admissions | Publications | Contact

@ Shanghai Institute of Optics and Fine Mechanics Tel:02169918000 沪ICP备05015387号-1 Technical support:Qingyun Software