Microfluidics is a rapidly emerging technology that enables miniaturization and integration for biological, chemical, and medical applications. The fluid mixing is an essential function required by most microfluidic systems, however, fast and efficient fluid mixing inside microchannels is usually difficult to achieve due to the laminar nature of microflows characterized by low Reynolds numbers. Recently, various passive mixers have been developed to achieve efficient mixing by utilizing three-dimensional (3D) geometric structures to induce disturbance in the fluids. Nevertheless, the fabrication of 3D microfluidic structures with arbitrary geometries is still challenging if not impossible, because today’s mainstream microfluidic fabrication techniques heavily rely on the well-established 2D planar lithographic approach.

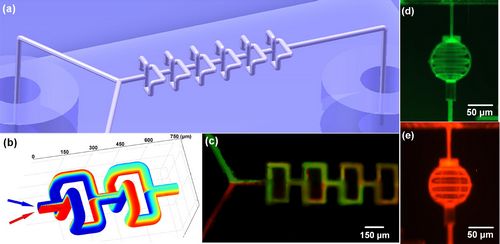

Researchers at State Key Laboratory of High Field Laser Physics, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences (SIOM, CAS) developed a new technique to fabricate microchannels in glass with nearly unlimited lengths and with arbitrary geometries. The main fabrication process includes two steps: (1) direct formation of hollow microchannels in a mesoporous glass substrate immersed in water by femtosecond laser ablation; and (2) postannealing of the glass substrate at 1150℃. This consolidates the nanoscale pores by causing them to collapse. However, the fabricated microchannels survive due to their larger size. Based on this newly established technique, a passive microfluidic mixer consisted of geometrically complex 3D microchannels was demonstrated, as illustrated in Figure 1a. The superior mixing efficiency of the 3D mixer is also confirmed by numerical simulations as well as mixing experiments, as shown in Figures 1b and 1c, respectively.

The dimensions of channel can be easily changed by controlling the machining parameters, such as the numerical aperture of objective, the laser pulse energy and the translation speed. To show this capability, a 3D microfluidic lantern composed of 3D microchannels with different sizes was fabricated by this technique. When either fluorescein sodium solution or Rhodamine B solution was injected into the microchannel and excited by a laser operated at 490nm or 540nm wavelengths, the lantern produced either green or red colors, as shown in Figures 1d and 1e, respectively.

The technique is promising for a broad spectrum of microfluidic applications based on compact and complex 3D microfluidic networks in the future.

This work is supported by National Basic Research Program of China (2011CB808100) and National Natural Science Foundation of China (10974213, 60825406, 11174156, 61108015).

This work has been published on LabChip. 2012, 12, 746–749.(http://pubs.rsc.org/en/Content/ArticleLanding/2012/LC/c2lc21015k) and reported in SPIE Newsroom, DOI: 10.1117/2.1201203.004150. (http://spie.org/x86371.xml?ArticleID=x86371).

|

| Figure (a) Schematic 3D diagram of the passive microfluidic mixer, (b) Numerical simulation of mixing result, (c) Fluorescence microscopy image of mixing experiment, (d) and (e) Fluorescence microscopy images of the Chinese lantern filled with green and red fluorescent dyes, respectively.(Image by SIOM) |